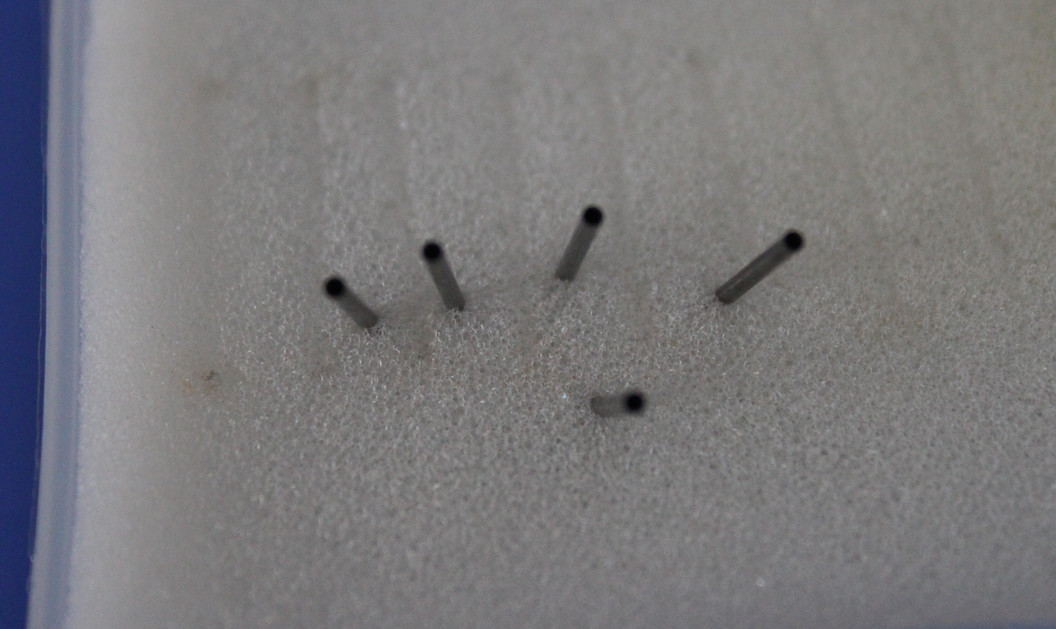

Large Cavities Steel Cylinder Sleeve , Round Carbide Wear Parts Sleeve

Technical parameters:

As a typical representative of super-hard metals and the industrial tooth, cemented carbide is widely used as core working parts in oil, gas, automobile, ships, steel, mines and other large-scale industrial production, for its advantages of good wear resistance, corrosion resistance, high hardness, high strength, especially in some special extreme working environment. Its good performance and long service life are effective to improve industrial production efficiency.

According to customer's drawing requirements, the specifications of conventional tungsten carbide pipe and tungsten steel pipe sleeve are as follows:

- The maximum outer diameter: φ74mm

- The minimum outer diameter: φ5mm

- The maximum inner diameter: φ68mm

- The minimum inner diameter: φ0.1mm

- The length of carbide pipe: 360mm

The main specifications for the current hard alloy pipe are as follows:

- φ16×φ1×330

- φ18×φ2×330

- φ20×φ4×330

- φ25×φ4×330

- φ30×φ4×330

- φ35×φ10×330

Advantages:

As a cemented carbide production and processing manufacturer, relying on the advanced carbide technology and complete industry chain in Zhuzhou, we provide customers with hard alloy sleeves, carbide mold parts, tungsten steel large-cavities, wear-resistant non-standard shaped carbide products. according to the customer's drawing requirements and our professional production equipment and rich experience as guarantee, we select high-quality materials to meet customers' demand. Especially for the high-precision refined mold products, from raw material selection to finished carbide mold parts, each procedure is strictly controlled and is in accordance with the customer's drawing requirements.