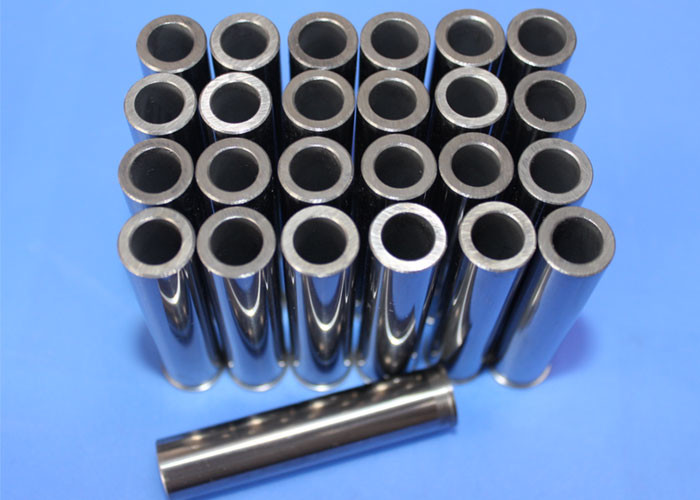

Machinin Tungsten Carbide Metal Sleeve , Small Tungsten Carbide Bushing

Tungsten Carbide Metal Sleeve Introduction:

Bush is a kind of plain bearings is to deruce frition and wear-axis motion designed out,the cost is relativeity Rolling cheaper, but friction is large,so use on the part of the member.Most bushing are made od copper, but also made of plastic bushings.Multi-sleeve is placed on the shaft and the supporting structure, and very close to the supporting structure, can rotate on the shaft sleeve only.

Technical parameters:

The wear-resistant hard alloy mold sleeves are custom-made according to the drawings of the granulation equipment manufacturer. The specification is φ14*1*φ13*φ9*60.

The 1mm cemented carbide sleeve is mainly used for assembly. Because of the high hardness of the cemented carbide and the relatively flimsy hanging table, the transportation requires special attention to avoid the impact deficiency of assembly. A granulation equipment needs 250 pieces of wear-resistant cemented carbide molds, with the requirements of uniform dimension and good physical stability.

Advantages:

The machining tolerance of cemented carbide processing is ±0.002. Carbide die sets are customized for production and processing. According to the specific requirements of customers, it is customized for specific series of corrosion resistance, high temperature resistance, wear resistance, acid and alkali resistance. Relying on the complete cemented carbide processing industrial systems and technology in Zhuzhou, we can provide high-quality wear-resistant parts, tungsten carbide alloy bushings, carbide die sets, carbide shafts, carbide bushings, carbide sleeves, etc.