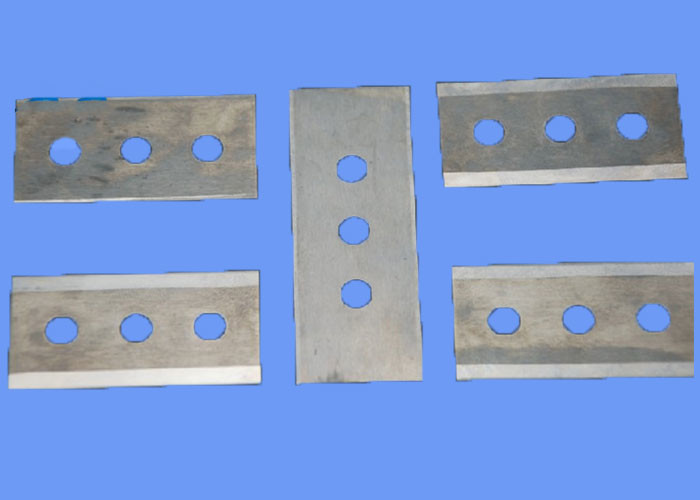

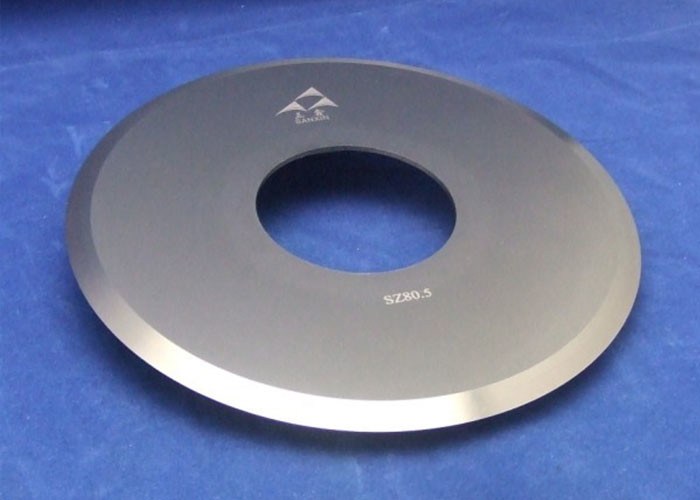

Milling Tungsten Carbide Cutting Tips , Structured Tungsten Carbide Cutter

Product Application Machine:

Used on CNC saw machine

Cutting Machine

melamine or laminate chipboard,MDF,composite materials

Zhuzhou sanxing Cemented Carbide Co., Ltd. Professional cemented carbide (tungsten steel) cutting tools manufacturer. Our whole cemented carbide (tungsten steel) saw blade milling cutter belongs to super-hard material saw blade milling cutter. Its hardness and cutting force are higher than that of high-speed steel saw blade milling cutter, which is beneficial for improving speed and feed rate, thus improving productivity. Our cemented carbide saw blade milling cutter is mainly used in milling tough and rigid materials like heat-resistant steel, stainless steel, etc.

Zhuzhou sanxing Cemented Carbide Co., Ltd. will wholeheartedly try our best to meet your requirements for the use of cemented carbide (tungsten steel) saw blade milling cutters.

Technical parameters

Specifications and service performances of straight teeth (A) and helical teeth integral tungsten steel saw blade milling cutters

| reference photos of straight tooth (type a) integral tungsten steel saw blade milling cutter |

| |

| No. | OD

φ=mmm | ID

φ=mmm | Thickness

S=mm | Common teeth number

T | Material grade and use

| Similar international grade |

| High quality domestic | Processing material | High quality imported | Processing material |

| 1 | 8 | 3~5 | 0.2~2.0 | 8,12,24 | PY40T | Cast iron

quenched steel

nonferrous metals

Nonmetal

etc. | TW15 | Negative low carbon Medium carbon steel Nonferrous metals Nonmetal etc.

| YK01 |

| 2 | 10 | 4~6 | 0.2~2.0 | 8,12,24 |

| 3 | 12 | 4~6 | 0.2~2.0 | 12,16,32 |

| 4 | 16 | 5~6 | 0.2~2.5 | 12,24,48 |

| 5 | 20 | 5~8 | 0.2~3.0 | 24,32,48 |

| 6 | 24 | 5~8 | 0.2~3.0 | 32,48,56 |

| 7 | 25 | 5~8 | 0.2~3.0 | 32,48,64 |

| 8 | 32 | 5~8 | 0.2~3.5 | 48,64,72 |

| 1 | 40 | 8~12.7 | 0.2~4.0 | 24,32,40 | YS2T | Carbon steel

high temperature alloy

stainless steel

high manganese steel

silicon steel

titanium alloy

etc. | TSM2 | Carbon steel

high temperature alloy

stainless steel

high manganese steel

silicon steel

titanium alloy

resin

fiber

graphite

etc. | YK02 |

| 2 | 45 | 8~16 | 0.2~4.0 | 32,64,80 |

| 3 | 50 | 12.7~16 | 0.2~4.0 | 64,80,100 |

| 4 | 63 | 16 | 0.2~6.0 | 64,80,100 |

| 5 | 75 | 22 | 0.2~6.0 | 64,80,120 |

| 6 | 80 | 22 | 0.3~6.0 | 64,80,120 |

| 7 | 90 | 25.4 | 0.2~2.0 | 80,100,128 |

| 8 | 100 | 25.4 | 0.5~8.0 | 80,100,120 |

| 9 | 125 | 25.4 | 0.7~10.0 | 80,100,120 |

| 10 | 130 | 27 | 1.2~10.0 | 80,120,160 |

| 11 | 140 | 32 | 0.2~2.0 | 120,160,180 |

| 12 | 150 | 40 | 0.2~2.0 | 120,160,200 |

notes:

1. When you place an order, please indicate the processed materials so that we can design the tooth shape and angle of the saw blade. Examples of filling in order specifications:Dφ×dφ×S

2. Saw blade’s tooth number, ID, OD and thickness can be customized.

There are twoo integral tungsten saw blade milling cutter’s tooth shapes--straight tooth (type A) and helical tooth, mainly used in clocks, glasses, motors, electronics and other industries. - Type A integral tungsten steel saw blade milling cutter is mainly suitable for processing the following materials: ordinary steel pipe, cast iron, non-ferrous metal, non-metal. It is suitable for shallow grooves.

- Reference cutting speed of type A integral tungsten steel saw blade milling cutter: low, medium and high speed cutting.

- Our company provides the service of repairing serrated teeth for customers.

|

Configuration advantages:

cemented carbide production expert specializing in cemented carbide raw material grade formulation, blank production and deep processing. Our cemented carbide saw blade milling cutter has the following advantages:

1. Professional material engineers specially select and match ultra-fine raw powder according to customer's requirements.

2. The products made by pressing and sintering with professional equipment and unique technology have good internal metallographic structure. It has precise size, which is easy to process. Therefore, the processing time and material loss are lessened.

3. A wide range of grades. Professional materials are specially designed for different uses to meet your different requirements.