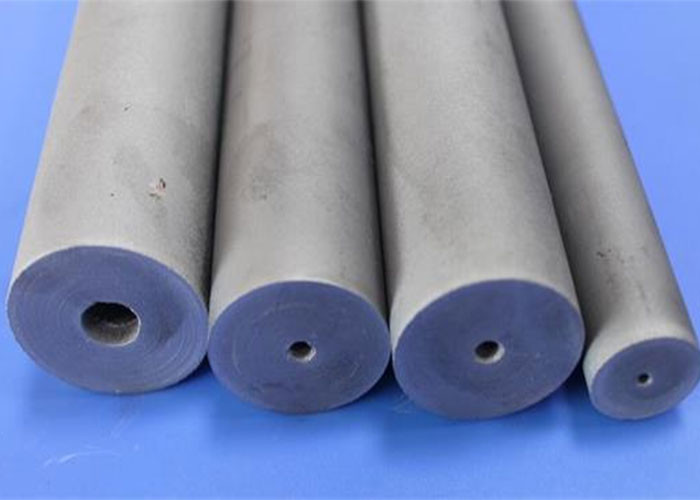

Molds Hardened Steel Sleeves / Wear Resistance Carbon Steel Sleeves

Hardened Steel Sleeves Introduction:

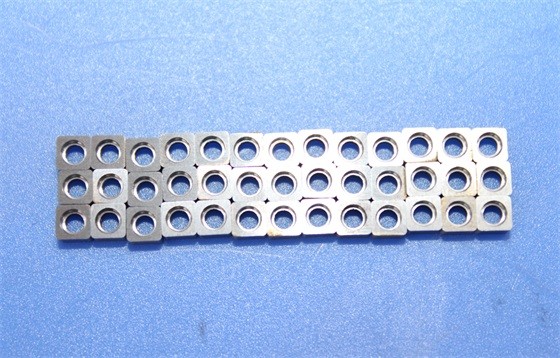

We can produce non-magnetic tungsten steel mold cavity used for the AR8 magnetic ring rotor mold.

Mold is a major industrial equipment. As an important means in the industrial production and as the direction of technological development, the mold manufacturing industry depend to a large extent on the development of modern industries and the improvement of the technical level. Our company provides non-standard cemented carbide mold. The precision can be ±0.002 to meet the customers' requirements.

Conventional cemented carbide mold products are weakly magnetic. The non-magnetic hard alloy molds require customized production and processing. The magnetic ring rotor upper cavity used in the AR-8 magnetic ring rotor mold requires non-magnetic carbide mold. Non-magnetic cemented carbide refers to hard alloy material that is not magnetic. The molding die for production of magnetic materials requires to use non-magnetic materials. In the past, non-magnetic steel has been used to manufacture mold, which mold performance is poor, the hardness is low, the service life is short, and the inner wall of the mold is severely pulled and deformed after a period of use. All these affect the dimensional accuracy and surface quality. The non-magnetic hard alloys, with its excellent performance, can effectively improve production efficiency.

| Name: | Hardened Steel Sleeves | Pin Ceramic Nozzle: | Costum |

|---|

| Tungsten Steel Slider Insert Head: | Costum | Feature: | Wear Resistance |

|---|

| Model: | Tungsten Steel Mold | Tungsten Steel Pin: | Double-hole Insert Head |

|---|

Hardened Steel Sleeves Advantages:

Carbide materials and molds are provided according to customer's specific requirements. As a cemented carbide production and processing manufacturer in Zhuzhou, we have been committed to providing precision tungsten steel products for the mechanical industry production. The accuracy tolerance of the tungsten carbide machining can be ±0.002.