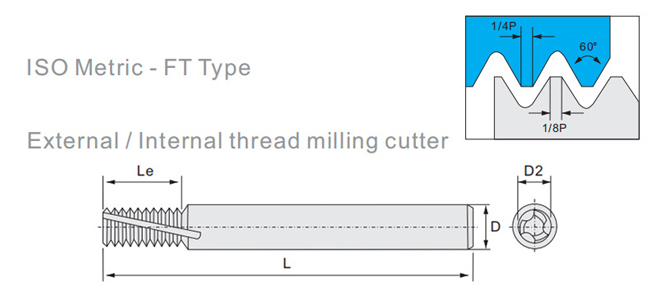

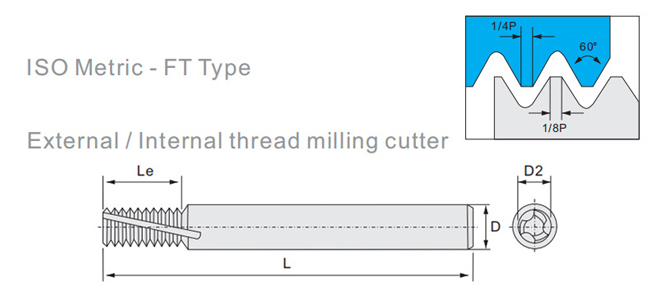

No Coating Multi-Teeth Carbide Thread Milling Cutter For Low Hardness Material

Application Field:

The Multiple Teeth internal thread milling cutter without Coating is used for large batches of workpieces of the same specification with high efficiency, suitable for deep processing of large inner diameter, 3 times the length of small-end diameter could be better.Besides, your particular demands will always be met due to our outstanding R&D team and standardizing factory production. Welcome to contact us!

Product Details--Multiple Teeth Milling Thread Cutters

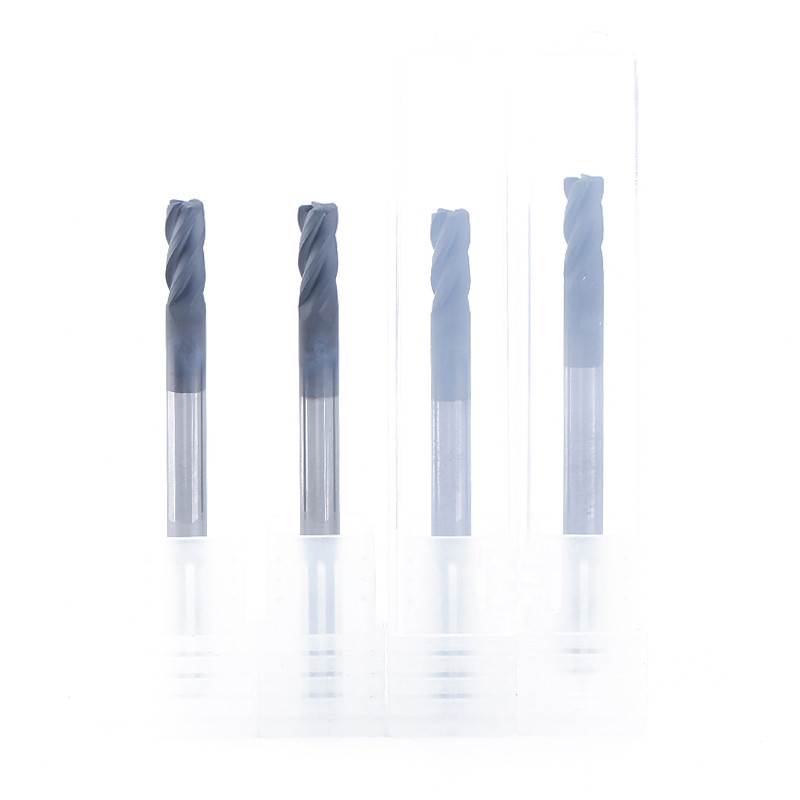

- Material :Tungsten Carbide, 100% New Material with high wear resistance and hardness.

- Usage:Mainly used for mass production and large diameter inner hole thread processing with high efficiency,suitable for processing aluminum, copper and other low hardness alloy materials

- Hardness: HRC 45/55 Degrees.

- Specification:Multiple-teeth,M2.5~M20

- Shank Diameter:4~16mm

- Coating : No coating.

- Grinding process: Introducing mirror grinding technology,leads your machining product to higher finish.

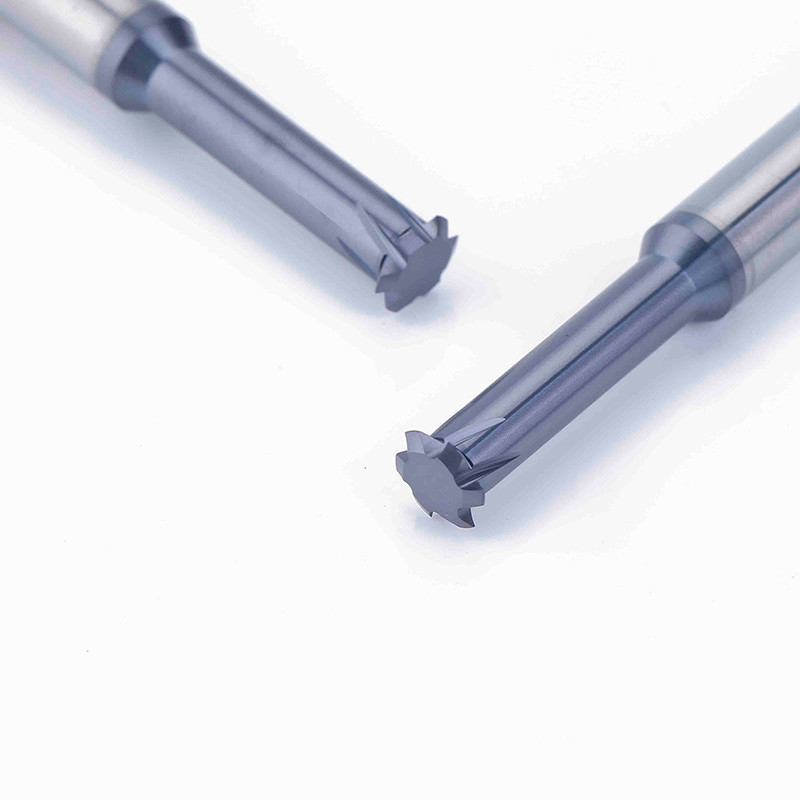

- Chip removal design: Large-capacity chip flutes design, improve your production efficiency.

- Customization:Please attach CAD drawings/3D drawings to your customized inquiry, thank you

Specific product information as below:

| Brand Name: | Drow |

| Model Number: | Multiple-teeth Internal Thread Milling Cutter |

| Customized support: | OEM, ODM, OBM. |

| Standard | ISO |

| Product type: | Milling Thread Cutter |

| Material: | Tungsten Carbide, 100% New Material |

| Coating: | without coating |

| Hardness: | HRC 45/55 Degrees |

| Specification | Multiple-teeth,M2.5~M20 |

| Shank Diameter | 4~16mm |

| Sample Order: | Acceptable |

| Usage: | used for mass production and large diameter inner hole thread processing with high efficiency |

| Applicable Material: | Suitable for processing aluminum, copper and other low hardness alloy materials |

| Compatible machine: | CNC machining center, engraving machine and other high-speed machines. |

| Machining type | Semi-Finishing/Finishing |

| Customization | Professional and Available |

Product Features:

1. Material selection: Tungsten steel round rods imported from Japan and Germany with stable quality and higher tool life.

2.Application Field: Multiple-teeth is used for large batches of workpieces of the same specification with high efficiency, suitable for deep processing of large inner diameter, 3 times the length of small-end diameter could be better.

3.Applicable Material:Suitable for processing aluminum, copper and other low hardness alloy materials

4.Burr-free cutting:The cutting edge is sharp and wear-resistant,has the characteristics of good chip removal,high processing efficiency,precise thread and high durability

5.Sharp and precise:Using mirror grinding technology,combined with large-capacity chip flutes,sharp and precise

Product Specification:

| Specifications | Size(mm) |

| D | D2 | L | Le |

| FT-M2.5*0,45-D4 | 4 | 2.1 | 50 | 6 |

| FT-M3.0*0.5-D4 | 4 | 2.3 | 50 | 6 |

| FT-M4.0*0.7-D4 | 4 | 3.1 | 50 | 8 |

| FT-M5.0*0.5-D6 | 6 | 3.9 | 50 | 10 |

| FT-M5.0*0.8-D6 | 6 | 3.9 | 50 | 10 |

| FT-M5.0*0.8-D4 | 4 | 3.9 | 50 | 10 |

| FT-M6.0* 1.0-D6 | 6 | 4.6 | 50 | 12 |

| FT-M6.0* 1.0-D4 | 4 | 4.6 | 50 | 12 |

| FT-M8.0*1.25-D6 | 6 | 6.5 | 60 | 16 |

| FT-M10"1.0-D8 | 8 | 8.7 | 75 | 20 |

| FT-M10*1,25-D8 | 8 | 8.2 | 75 | 20 |

| FT-M10*1.5-D8 | 8 | 8.2 | 75 | 20 |

| FT-M12*1.0-D10 | 10 | 10 | 75 | 24 |

| FT-M12*1.25-D10 | 10 | 10 | 75 | 24 |

| FT-M12*1.5-D10 | 10 | 10 | 75 | 24 |

| FT-M12*1.75-D10 | 10 | 10 | 75 | 24 |

| FT-M14*1.5-D10 | 10 | 12 | 75 | 28 |

| FT-M14* 2.0-D10 | 10 | 11.6 | 75 | 28 |

| FT-M16*1.5-D12 | 12 | 14 | 80 | 32 |

| FT-M16*2.0-D12 | 12 | 13.6 | 80 | 32 |

| FT-M18*2.5-D16 | 16 | 14.8 | 100 | 36 |

| FT-M20*2,0-D16 | 16 | 16 | 100 | 40 |

| FT-M20* 2.5-D16 | 16 | 16 | 100 | 40 |

Why choose us:

1.Technical innovation: complex surfaces and functional structures can be quickly formed and kept accurate.

2.Processing speed: short production cycle, fast delivery time, to ensure delivery on time according to the delivery date.

3.Product quality:Absolutely strict inspection. high quality guaranteed,high precision, up to 0.002-0.001mm.

4.Confidentiality system: triple confidentiality measures to protect, proofing more assured.

5.Fully equipped: excellent processing capacity, multiple production lines, advanced equipment, professional supporting facilities.

6.Cost-effective: reasonable design and material selection lead us to a competitive price, so that could help provide you more favorable price of the same level products .

FAQ

Q1:Do you produce special cutting tools?

A: Yes,we specialize in customized cutter fabricate and translate the most complex cutting idea into reality, tools manufactured by us are designed and customized for various demanding applications and variety materials!

Q2:Do you accept low volume for sample order? And what’s your MOQ for special tools?

A: Yes, we do. For sample order, MOQ one piece is accepted, and the sample lead time is 2-3 days. It can be negotiated for special requirement.

Q3:If we want to cooperate with you, is it possible to get confidentiality?

A: Sure, all your information including company info, drawings, PO details will be kept confidential, we can signed NDA if you want (non disclosure agreement).

Q4: What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q5: what can you buy from us?

A: Carbide insert,carbide end mill,carbide drill,carbide boring,cutting tools&customized carbide precision molds.

Q6: Who are we?

A:We are based in Guangdong Province, China, start from 2010,sell to Western Europe(10.00%),North America(20.00%),Eastern Europe(20.00%),Southeast Asia(40.00%),Africa(10.00%). There are total about 51-100 people in our factory.