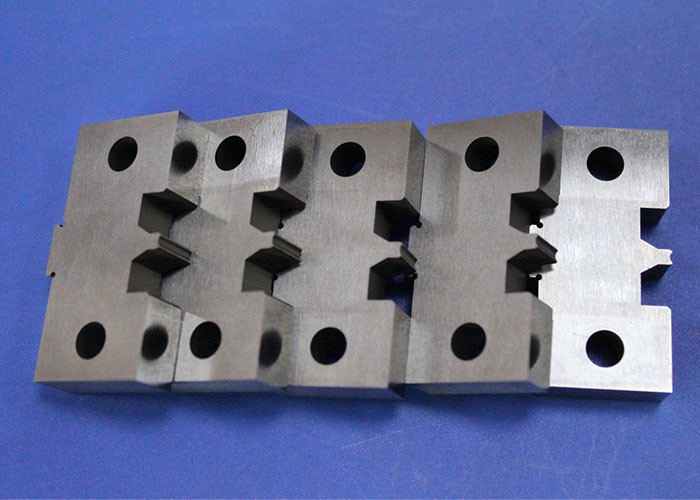

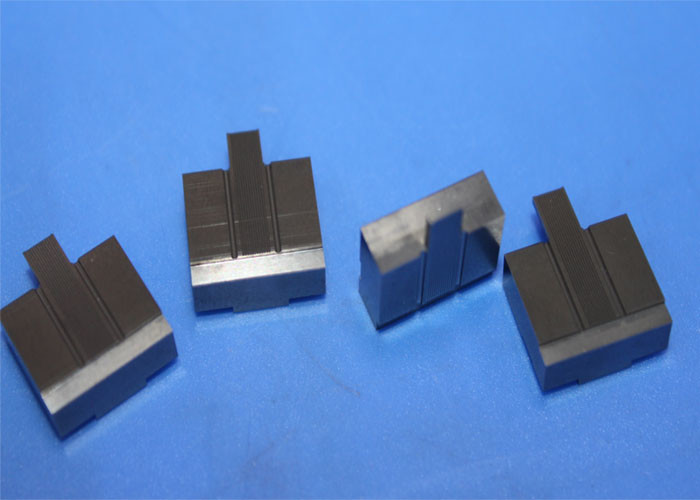

Non Magnetic Tungsten Carbide Processing Seat For Petroleum Industry

Introduction:

The demand for high-performance mold products in modern manufacturing has become an important method to improve production efficiency and economic development. For example, for the energy production industry, the high-quality equipment is the basic requirement for ensuring the long-term and safe operation of energy production lines. Thus, the performance requirements for mold products have become an inevitable focus. It is the high-end products of cemented carbide molds that have great promotion effects to aerospace, automotive, and downhole drilling industries.

Technical parameters:

The non-magnetic alloy tungsten steel mold valve core is a special alloy mold product, for the special classification of cemented carbide mold products. The non-magnetic hard alloy mold valve seat core is customized according to the drawings of Shenyang customers.

The high demand for mold products in industrial production is an inevitable requirement for social and economic development, and is also the demand for high-end material in the manufacturing industry. The customer was formerly a subsidiary of China Aerospace Science and Industry Corporation, and is responsible for the research and production of aerospace products and civilian products. Since 1982, it has provided manufacturing and repair services for imported equipment of domestic large-scale petrochemical enterprises. This company has focused on the manufacture and repair of gas compressor spare parts. At present, it has succeeded in the manufacture and repair of compressor seal packing, combination valve, static direction valve and other products, and has been used in many large petrochemical enterprises in China.

Advantages:

Non-magnetic alloy tungsten steel valve seat core is the essential supporting equipment for the petroleum industry. Our company also provides high-quality tool products for oil drilling. And we have been providing cemented carbide drilling tools for Bohai Oilfield. The key component of products must be resistant to acid and alkali corrosion and high wear resistance. The whole requirements are to meet the requirements of drilling engineering. In the processing and production of magnetic materials, large-scale non-magnetic alloy molds are also required, which is one of the main tool of powder metallurgy pressing. Cemented carbide is the most wear-resistant tool for its excellent performance. The non-magnetic cemented carbide mold provides high-quality product for industrial magnetic materials.