Introduction:

We can provide non-standard tungsten steel punch customization in accordance with customer drawings, in order to meet the special requirements of industrial production.

We also provide tungsten steel square punch, tungsten steel round punch, tungsten steel combination punch, tungsten steel perforated punch, tungsten steel blanking punch, tungsten steel shearing punch, tungsten steel internal thread punch and other series of tungsten steel die punches. As wear-resistant metal material, tungsten steel is the first choice for high-end wear parts, especially for some small and precise core working parts. The wear resistance performance of tungsten steel wear parts completely exceeds other metal materials. Of course, due to its high hardness and high wear resistance, the non-standard custom-made production is relatively cumbersome and troublesome. The tungsten steel wear-resistant parts tungsten steel processing. Especially the threaded tungsten steel parts machining requires much advanced equipment and much higher technology.

Using good material is an effective way to improve the production efficiency. The stability and long service life of tungsten steel punch are good choice for stamping die parts. The precision alloy die and punch require high precision and product consistency. Every punch must strictly meet the dimensional accuracy tolerance, thus can extend the service life of the die. As tungsten steel punch used in precision dies, product consistency is a key factor that will directly affect the service life and the dimensional accuracy of the dies. The precision requirements for the cemented carbide parts are μ-level precision. This requires strong technology and rich experience in cemented carbide deep processing systems with advanced production equipment to meet μ-level precision tolerance. As for the processing precision, the production precision alloy parts tolerance can be ± 0.002, concentricity and parallelism can be 0.002. The precision tolerance of the die parts can solve the overall accuracy.

National high-tech enterprise certification, the tungsten carbide accuracy of the shape tolerance can be ±0.002.

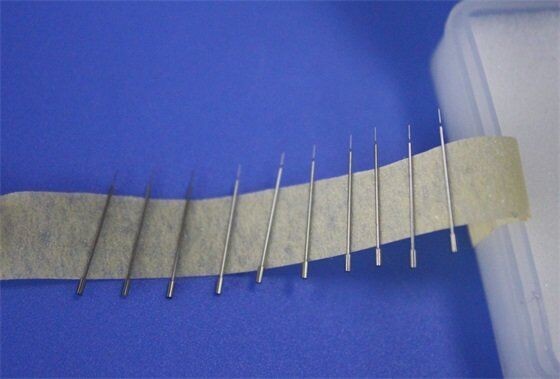

We can provide custom-made high precision tungsten steel punch needle, especially for ultra-fine and ultra-precision punching needle, core needle, our company has complete testing equipment to offer product parameters:

Tungsten steel nozzles: the minimum inner hole: Ø0.03mm ~ ±0.002mm;

Tungsten steel punching needles: the minimum outer diameter: Ø0.025mm ~ ±0.002mm;

Tungsten steel probes: R angle of the front end: Ø0.01mm ~ ±0.002mm;

Core needle sleeve type: The minimum outer diameter: Ø0.02mm ~ ±0.002mm

the minimum inner diameter: Ø0.07mm ~ ±0.002mm.

Tungsten steel punch internal thread die meets the tolerance requirement of ±0.002. High-precision production of tungsten steel punches take a long time with possible risk of scrapping rate. For this reason, customers need to contact us in advance so as not to delay the delivery time. We can provide high-precision die insert punch series, so that the precision dies have higher efficiency and longer service life.