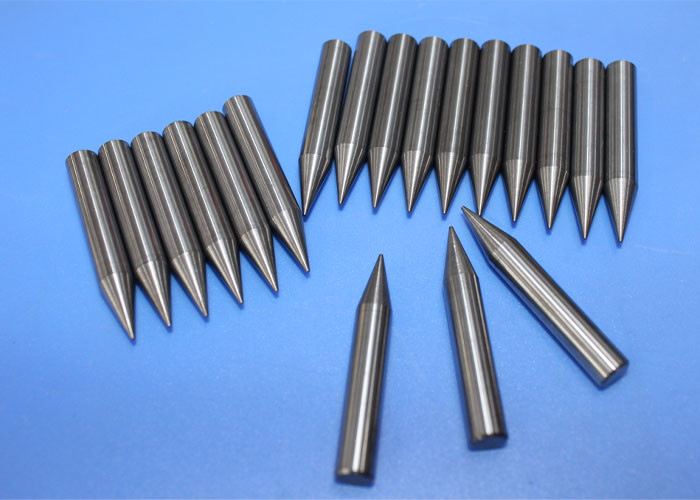

OEM Tungsten Carbide Processing Valve Guide Pilots Wear Resistance

Tungsten Carbide Processing Valve Guide Pilots Introduction:

1. 100% virgin raw materials.

2. Various kinds of grades are availalbe based on customer's application.

3. we have professional advanced production line and inspeciton equipments to ensure high quality products.

4. Precision Ground and high polishing process

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precise grinding.

Tungsten Carbide Processing Valve Guide Pilots Technical parameters:

Cemented carbide is a good choice for mold products due to its high hardness, high strength and high wear resistance. The alloy guide bushing belongs to the alloy mold series products. It is a wear-resistant product made by our company according to the precision specifications of Shenzhen customers' drawings. The specification of the cemented carbide guide bushing is φ12×φ8×16, the outer circle finish grinding and polishing mirror is 0.4, the inner circle is 0.4. The inner circle tolerance needs to be 0.005, the concentricity tolerance can be φ0.003, which belongs to high-precision r carbide mold products. It requires fine and careful work to ensure that every dimensional tolerance is perfectly met.

The cemented carbide guide bushing is made of high-quality carbide material, and processed and machined according to the drawing tolerance requirements. The product has good hardness and toughness and super wear resistance. It is a high-quality mold product for precision machinery. The physical parameters are as follows:

- Grain size (um): 1.0 ~ 2.0

- Cobalt content (Co%): 8.0

- Density (g/cm³): 14.41

- Hardness (HRA): 89.5

- Bending strength (Mpa): 3200

- Young's modulus (Gpa): 570

- Compressive strength (Mpa): 4700

The tungsten steel guide bushing is produced according to the customer's drawing precision requirements. The precision tolerance is 0.005mm, which is compatible with the long-wearing operation of mechanical equipment.