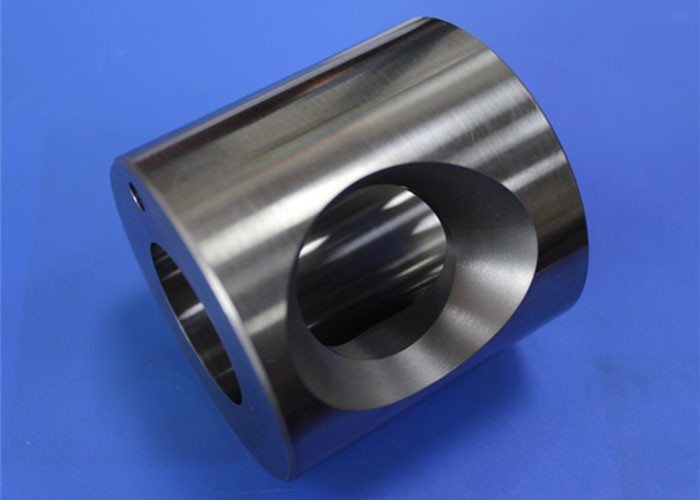

Oil Fields Tungsten Carbide Processing Valve Balls And Valve Seats

Valve Balls And Valve Seats Introduction:

1. Valve balls and valve seats are widely used in oil fields.

2. Valve Ball and Seat performance directly affects the use effect and service life of the sucker rod pumps.

3. Each ball-and-seat combination is vacuum tested to ensure a perfect seal is obtained in all positions of contact.

Valve Balls And Valve Seats Technical parameters:

We provide non-standard precision tungsten steel sleeve, tungsten steel tubes, tungsten steel bushings and other series of products. The conventional tungsten steel casing, carbide pipe and other dimensions are as follows:

1. The maximum outer diameter: φ74mm

2. The minimum outer diameter: φ5mm

3. The maximum inner diameter: φ68mm

4. The minimum inner diameter: φ0.1mm

5. Maximum length of tungsten steel pipe: 360mm

Valve Balls And Valve Seats Advantaegs:

For the long-term use of mechanical equipment, the wear resistance of tungsten steel, which is representative of super-hard metal, has excellent performance of wear resistance and corrosion resistance. As the industrial teeth, tungsten steel has excellent wear resistance, corrosion resistance and high hardness, and high strength. All these properties make them widely used as core parts in large-scale industrial production such as oil and gas industry, automobile ships, steel mines, motor rotors, etc. The good service performance and long service life of tungsten steel die is an effective way to improve production efficiency.