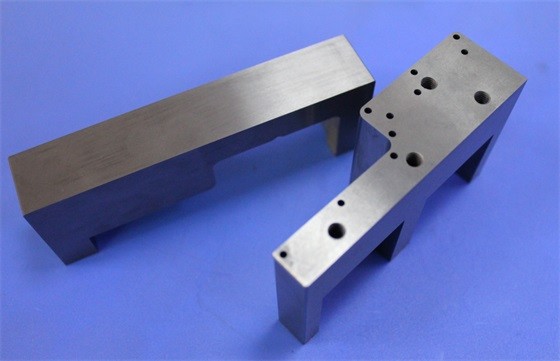

PCB carbide tool

As one of the representatives of super hard tools, carbide tools are powerful cutting tools in production. With the development of the electronics industry, the demand for PCB carbide tools has also been continuously developed.

Zhuzhou Sanxin PCB Carbide Tools, based on the rich experience and advanced technology of Zhuzhou cemented carbide tool, based on V-CUT processing of PCB circuit board, preferably select fine materials and unique formula. based on the specific model of V-CUT machine and the selection of ultra-fine particle raw materials, the V-cutting blade blank products formed by low-pressure sintering have good metallographic structure, uniform product densification. Advanced precision equipment and reasonable and precise deep processing technology makes the V-cutting tool having small tolerances and precise geometric tolerances. The PCB carbide tool has high hardness, high flexural strength, good impact toughness and high corrosion resistance, and high wear resistance. The V-CUT has a long service life and is designed to meet the maximum requirements of the efficiency of V-CUT operations, improving the productivity of customers and friends!

Configuration advantage

Due to the different PCB V-CUT operations, some customers have special specifications for PCBs, such as φ50, φ50.8, φ51.3, φ51.5, etc. -CUT tools. We can customize according to the specific needs of customers and friends, to meet the requirements of different PCB operations with quality and service.

Zhuzhou Sanxin PCB Carbide Tools are complete in specifications, and the common model are well-stocked, and the delivery can be arranged at any time. The specifications are delivered quickly, and the customer's production requirements can be met with the fastest response speed.

Technical Parameters

Circuit board V-CUT blade for PCB carbide tool, mainly used for V-CUT machine, solid carbide tool for V-CUT operation on PCB board, circuit board, aluminum substrate, FR-4 board, etc. There are:

1, φ56 × φ25 × 2.4, 32 teeth 40 teeth 48 teeth, angle 20 °, 25 °, 30 °, 35 °, 45 °;

2, φ51 × φ25 × 2.4, 32 teeth 40 teeth 48 teeth, angle 20 °, 25 °, 30 °, 35 °, 45 °;

3, φ51 × φ25 × 2.0, 32 teeth 40 teeth 48 teeth, angle 20 °, 25 °, 30 °, 35 °, 45 °;

4, φ39 × φ17 × 2.4, 32 teeth 40 teeth 48 teeth, angle 20 °, 25 °, 30 °, 35 °, 45 °;

5, φ32 × φ17 × 2.4, 32 teeth 40 teeth 48 teeth, angle 20 °, 25 °, 30 °, 35 °, 40 °;

6, φ28 × φ15 × 2.0, 32 teeth 40 teeth 48 teeth, angle 20 °, 25 °, 30 °, 35 °, 40 °

Of course, there are also PCB hard alloy V-CUT tools of φ66, φ90, φ95, φ100, φ110, φ120 and so on!

Configuration Advantage

Based on Zhuzhou cemented carbide production technology, Zhuzhou Sanxin cemented carbide tool is backed by Zhuzhou cemented carbide cutting tool. It is guided by V-CUT operation in PCB electronics industry. It strictly controls every production process from raw material to finished tool. Focusing on each production process , we provide high-performance PCB carbide tools for the electronics manufacturing industry to meet the needs of customers' V-CUT operations.

After sales service

Zhuzhou Sanxin Cemented Carbide Production Co., Ltd. promise:

1. Each piece of the factory blade will have a digital security identification code to ensure that you are buying the original authenticity produced by Zhuzhou Sanxin Company.

2. The customer will complete the product delivery within one working day after the order is placed. The specific method is mainly based on express delivery.

3. All the cut legs blades that are manufactured by our company will have detailed instructions for use.

4. Based on the use characteristics and applicability of the carbide cut legs blade, we solemnly promise that after customer first using the cut legs blade (ie, does not sharpen the knife after use), comes out the applicability is not strong, we provide replacement, return and technology guided services to meet customer needs.

5. We are committed to quality production and integrity.

6. Our company can provide customers with detailed cut legs blade use solutions.