| Grade | Co% | Density g/cm³ | Hardness HRA | Bending strength Mpa | Elastic Modulus Gpa | Application |

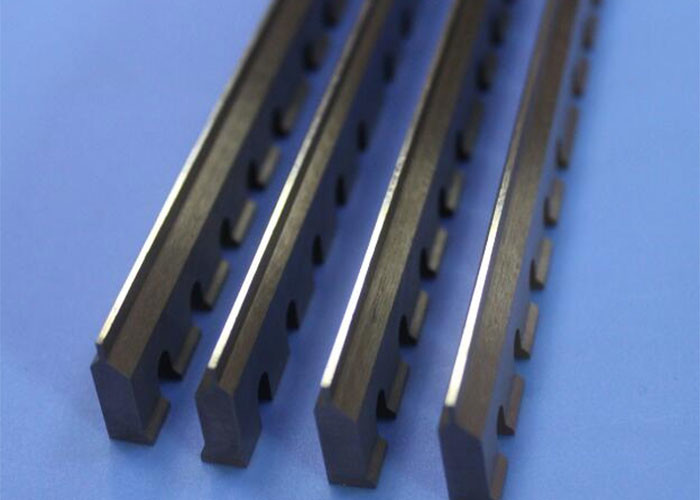

| SX05B | 6.5 | 14.8 | 91.5 | 2800 | 525 | Good wear resistance, suitable for simple cavity mold. |

| SX30 | 9 | 14.6 | 90.5 | 3200 | 500 | Highly versatile, suitable for soft magnetic materials, iron-based, copper-based powder molds. |

| SX10 | 10 | 14.4 | 92 | 4000 | 490 | Ultra-fine grain alloy, excellent wear resistance and strength, highly versatility, suitable for soft magnetic, iron-based and copper-based powder molds. |

| SX20 | 13 | 14.2 | 90.5 | 4000 | 460 | Ultra-fine grain, moderate hardness, high strength, good wear resistance, suitable for relatively complicated shaped molds. |

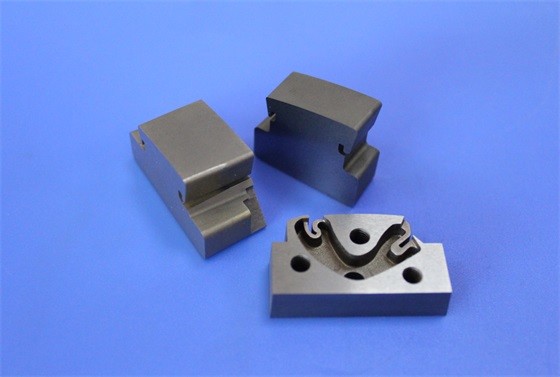

| SX40A | 12 | 14.2 | 89 | 3400 | 470 | High strength, suitable for complex internal cavity molds. |

| SX45A | 15 | 13.9 | 87 | 3300 | 440 | Good comprehensive performance, high strength and excellent electrical processing performance, suitable for molds with complex cavities. |

| SX50A | 20 | 13.4 | 85 | 3100 | 390 | Good toughness, good impact resistance, good electrical processing performance, suitable for complex molds under high load. |