The Particleboard diamond saw blade dry cutting operation is a high quality machine saw blade for large woodworking machinery’ production and processing. Diamond saw blade is the representative of dry cutting technique with its ultra high hardness. It is the nemesis of high hardness material sheet such as wood particleboard, MDF, veneer, wood floor and middle layer board!

The rapid development of social economy For woodworking manufacturers, in order to improve competitiveness, we must improve production efficiency. Cemented Carbide is widely used as an industrial tooth,Specific to large scale wood production, it’s limited of traditional carbide saw blades’ performance for high hard particleboard operations. As one of the hardest saw blade tools in the world, diamond is no more than 50-150 times harder than cemented carbide. In the continuous and long lasting dry cutting operations woodworking machinery production,it’s very obvious that ultra high hardness of diamond saw blade can improve the production efficiency.

Based on the Zhuzhou cemented carbide insert production technology, combined with years tool manufacturing experience, Zhuzhou Sanxin diamond saw blade is made of German high quality alloy steel as the base, using excellent performance composite diamond cutter head , simultaneously formed by Spark mechanical electro grinding technology .The whole mechanical process is standardization flow operation, to ensure the consistency of every detail of the production process, the well designed dynamic balance and the scientifically heat dissipation can solve the continuous long life cutting on the woodworking machinery production line,powerful cutting tool for the particle board, High density MDF and high speed super finishing. Based on the actual results of customers in Foshan, Guangdong Province, excellent performance for base, the on site test for standard ,it can be used continuously for 300-400 hours; with good wear resistance and can be repeatedly Grinded, the maximum using time can reach 4000 hours. /sheet. It provides a strong product technical support for woodworking operations, eliminating many troubles in replacing the tool and minimizing the production cost of the enterprise.

Sanxin diamond saw blade chipboard dry cutting operation, the actual effect exceeds the production of 40-50 pieces of carbide saw blade, the comprehensive cost which greatly reduces for the woodworking machinery cutting operation. Professional knife, there must be tricks! Zhuzhou Sanxin Diamond Saw Blade provides strong product and service support for wood machinery processing operations. We believe that our quality and technology will bring you more affordable effects!

Technical Parameters

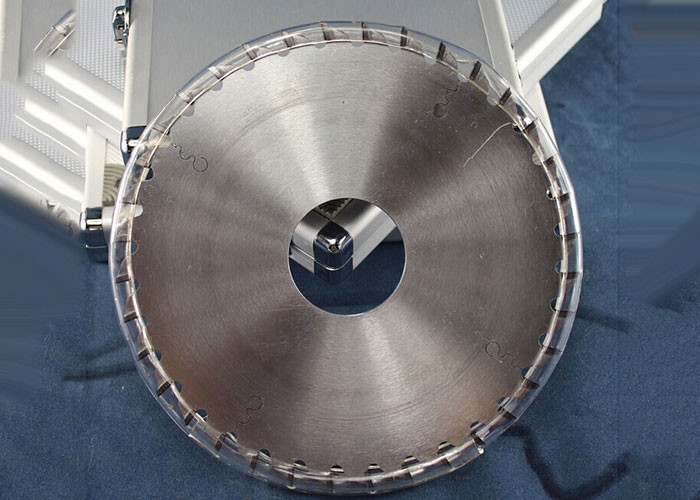

Diamond saw blade for chipboard dry cutting, Zhuzhou Sanxin PCD diamond saw blade is professional for particle board continuous and long lasting dry cutting operation, the detailed physical parameters of the diamond saw blade are as follows:

Product parameters: diamond saw blade

Product specifications: φ300 × φ30 × 3.2 × 96T × 11 °

Diamond saw blade for particleboard dry cutting, is used for large woodworking operations, the product specification is φ300 × φ30 × 3.2 × 96T × 11 °, German high quality alloy steel as the base, high quality PCD composite diamond cutter head welded as forming, with good dynamic balance and scientific heat dissipation design ,ensuring the longevity of wood chipboard production cutting work. The regular using period is at least one month. The experimental test completely surpasses the service life of 50 pieces of carbide saw blades on the market.

Professional knife, there must be tricks. As a professional manufacturer of Zhuzhou cemented carbide inserts, we have been committed to providing high quality cutting tools for industrial production cutting. Science and technology as the primary productivity ,also it is a good performance of innovative operations. Taking woodworking machinery cutting operations as an example, the excellent performance of PCD saw blades is suitable for vertical cross section single and double veneers, multi layer boards, particle boards, etc., arranged in precision electronic saws and push table saws.

The PCD woodworking saw blades manufactured by our company are made of German high quality alloy steel, simultaneously formed with excellent performance composite diamond cutter head by EDM mechanical electro grinding technology. The whole process is standardized by mechanical flow, ensuring the consistency of every detail of the production process. The well designed dynamic balance and scientifically created heat dissipation solve the continuous long life cutting of woodworking machinery production line. It is a powerful wealth cutting tool for particleboard, high medium density board and high speed super finishing.

After sales service

Diamond saw blade for chipboard dry cutting operation, as a professional cutting tool manufacturer, our company's high quality particleboard woodworking diamond saw blade for woodworking cutting operations, especially for hardboard materials such as particleboard, veneer, high density MDF, wood flooring. In order to enhance the customer's confidence and make customers and friends understand the performance and economic indicators of PCD diamond saw blades, our company promises to change the cutting life of wood chip saw blades. It can work continuously for one month based on 8 work hours per day. The cutting performance of the PCD composite diamond saw blade completely exceeds the service life of 40-50 pieces of carbide saw blade, the price and cost are more favorable, and the after sales service of the refining blade is free.

Our company's diamond saw blade adopts German high quality alloy steel as the base for the dry cutting operation of particleboard. The high performance PCD composite diamond cutter head is precisely formed, and the whole process is mechanically standardized. The production process ensures the consistency of every detail of the production process and the well designed dynamic balance and the scientific heat dissipation ensures that the PCD composite diamond saw blade is consistent with service life of woodworking cutting operation. It can be used for more than 300-400 hours continuously, and can be used for multiple times to ensure the best service life. The maximum use time is 4,000 hours/piece, and the company provides powerful product technical support for woodworking furniture cutting operations to maximize production efficiency and reduce production costs.