Particleboard woodworking saw blade, as a woodworking diamond saw blade, specializes in wood chipboard cutting production and processing operations, diamond saw blade is the best quality woodworking saw blade tool, none of them. Wood chip saw blades, specializing in wood chipboard, wood flooring, MDF, veneer cutting operations, is a high quality display of woodworking dry cutting operations.

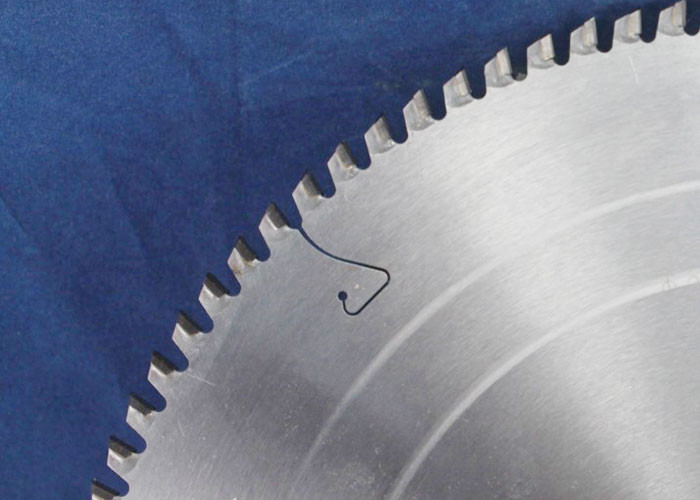

Particleboard woodworking saw blade, scientific name is PCD composite diamond saw blade, has become the hardest material cutting tool, and the leader of woodworking dry cutting tools. Its superhard performance and high durability are the nemesis of woodworking materials. The PCD composite diamond saw blade produced by our company is made of German high quality alloy steel as the base. The composite diamond cutter head with excellent performance is simultaneously formed by EDM mechanical electro grinding technology. The whole process is mechanically standardized and the flow is guaranteed to ensure every detail of the production process. Consistent, well designed dynamic balance and scientifically created heat dissipation, solving continuous long life cutting on woodworking machinery production line, it is a powerful wealth cutting tool for particleboard, high medium density board, high speed super finishing. Excellent performance as the basis, on site experimental testing standards, can be used continuously for 300-400 hours; strong wear resistance can be repeatedly honed, the maximum use of scrapping time can reach 4000 hours / piece. This provides a strong product technical support for woodworking operations, eliminating many troubles in replacing the tool and minimizing the production cost of the enterprise.

Diamond is currently the hardest tool material in the world and is generally 50-150 times harder than cemented carbide materials. Due to the high manufacturing cost, hard hardness, strong wear resistance, high processing difficulty, high manufacturing threshold and high price, it has been difficult to popularize woodworking machining cutting operations.

In wood processing, especially for particleboard, veneer, high density MDF, wood flooring and other materials with high impurity and hardness, PCD composite diamond saw blade is the nemesis. At present, the best quality alloy circular saw blades on the market must be dismantled for a half or one day. Since the daily tool change frequency ,which seriously affects the productivity, the cost of the saw blade is also greatly improved, which reduces the processing quality of the woodworking products. The particleboard woodworking saw blade produced by our company, named PCD composite diamond superhard circular saw blade, has excellent performance, high wear resistance, high toughness and high heat resistance. Its service life is 40-50 pieces of hard alloy round. The effect of the saw blade, its acid resistance, edge is not easy to passivate, processed wood’s high quality , the daily tool change and sharpening time is reduced, the production cost is reduced, the processing quality and efficiency are improved, and it is the first choice to replace the alloy circular saw blade.

If you want to do something good, you must first sharpen your tools! Zhuzhou Sanxin Particleboard Woodworking Saw Blade is specializing in the production and processing of large scale wood, furniture and board industry. It is a high quality saw blade for dry cutting of particleboard. We welcome customers and friends of woodworking production cutting operations to contact Sanxin. We will provide the best quality. Product and technical service support!

Particleboard woodworking saw blade, Zhuzhou Sanxin diamond saw blade is professional for woodworking chipboard cutting processing and woodworking diamond saw blade. It is a high quality saw blade for long term effective and high quality wood particleboard processing.

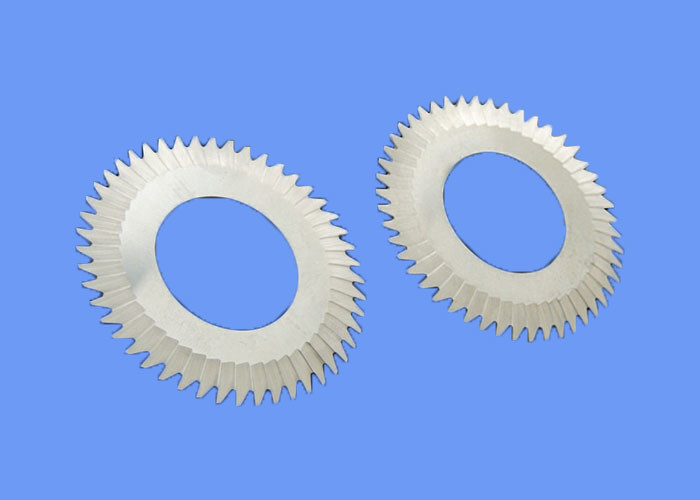

Product Name: Wood chip saw blade

Product Specifications: φ300 × φ30 × 3.2 × 96T × 11 °

Continuous operation time: 300-400 hours

Configuration advantage

As a professional manufacturer of Zhuzhou cemented carbide inserts, we have been devoted in high performance cutting tools for machining and cutting operations. In order to meet the needs of our customers' wealth cutting tools, our new PCD diamond saw blades are specially designed for chipboard cutting operations,making it a high quality cutting tool for woodworking furniture production.

Science and technology is the first productive force. Our company combines many years of experience in tool manufacturing, and the advanced PCD composite diamond manufacturing technology as the premise. It adopts EDM mechanical simultaneous molding and grinding technology, which is specializing in woodworking processing in particleboard, veneer and high school density. Boards, wood floors and other high impurities ,high hardness wood materials ,have significant processing effects.

Specializing in knife, there must be a trick, our company's many years of experience in cutting tool production operations as a basis, combined with woodworking cutting operations for large scale wood products cutting processing to provide strong product services and technical support!