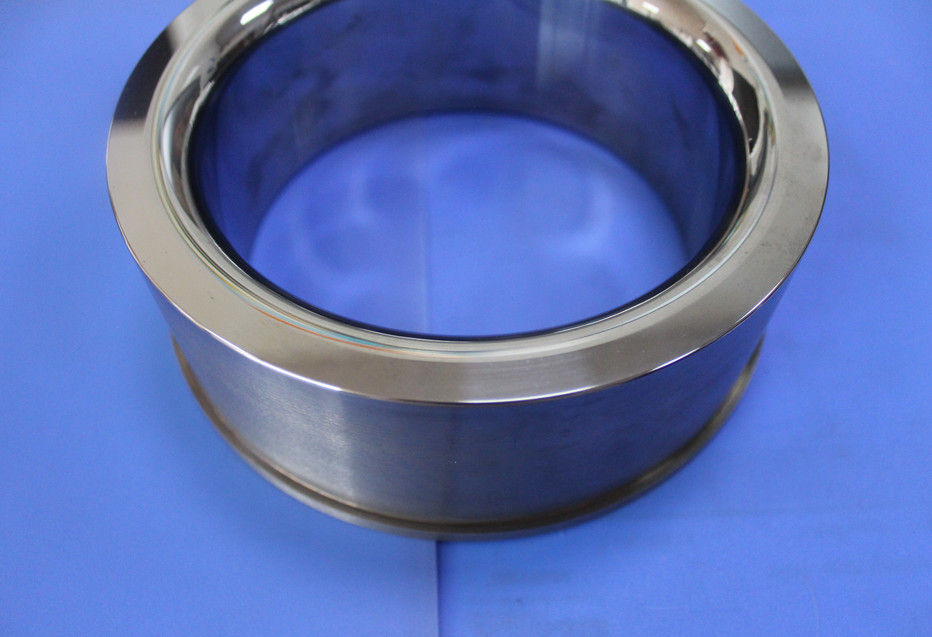

Precision Tungsten Carbide Wire Drawing Dies / Carbide Cold Forming Dies

Tungsten Carbide Wire Drawing Dies Introduction:

1. custom tungsten carbide wearproof mould parts supplier

2. High quality cemented carbide raw material

3. Mature processing technology

4. Product deformation small, molded parts made to order.

5. Welcome to design and sample customized non-standard products

6. Full range of types available, more convenient for you to purchase;

7. Various grades available, therefore can provide full machiningsolutions

8. Produced with precision molds, the products have better dimensional accuracy and uniform;

9. Careful surface treatment, ensuring perfect appearance, increasing customer satisfaction;

10. Made of top-quality raw material, have more stable properties, also extend its service time.

As the industrial tooth, cemented carbide used as key part of drilling has better performance and efficiency than other materials. Cemented carbide products have provided oil exploration, drilling engineering and geological mining operations with powerful performance support. As a major manufacturer of hard alloys, the cemented carbide industrial chain in Zhuzhou leads the industry.

Bohai Drilling Engineering Technology Research Institute provides detailed drawings, which require that the cemented carbide key components must have acid and alkali resistance, corrosion resistance, high wear resistance, and good impact resistance. these requirements are to achieve drilling. Our company adopts high-quality materials as the basis for deep processing operations. There are 4 drawings of this product. Our company has completed delivery for more than one month from the selection of materials to the finishing of finished products. From material selection to finished product precision processing, each production process is strictly implemented to achieve the requirements of cemented carbide products. we can provide customized production of non-standard hard alloy products, and guarantees the best use value of customers based on customer's drawings and samples.

Technical parameters:

Bohai Drilling Engineering Technology Research Institute provides detailed drawings, which require that the cemented carbide key components must have acid and alkali resistance, corrosion resistance, high wear resistance, and good impact resistance. these requirements are to achieve drilling. Our company adopts high-quality materials as the basis for deep processing operations.

Advantage:

As the industrial tooth, cemented carbide is best tool for manufacturing. As a cemented carbide production manufacturer in Zhuzhou, relying on Zhuzhou 60-year cemented carbide military production technology and industrial chain in Zhuzhou, we provide customers with high-quality hard alloy wear-resistant parts and non-standard shaped carbide products. Based on customer's drawing requirements, we select high-quality materials to satisfy customers' use demand.