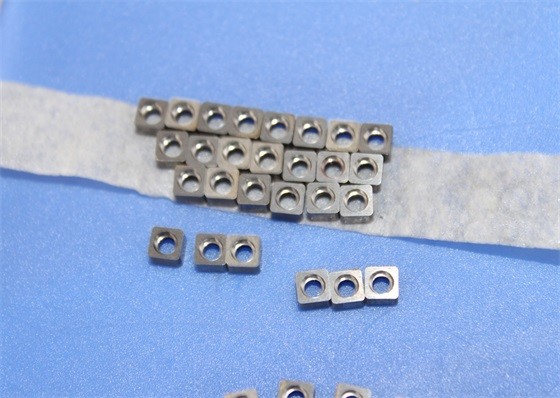

Precison Location Tungsten Carbide Sleeve High Temperature Resistance

Introduction:

According to customer requirements, we can provide non-standard high temperature carbide mold materials and high temperature carbide flanges.

As a typical representative of super-hard metals, cemented carbides have excellent high-temperature resistance and physical stability, especially as a high-temperature mold material, suitable for extreme environmental production and processing requirements. High-temperature carbide flanges used in accordance with customer drawings require the following standards:

1. long-term high temperature (of 800 °C) tolerate, no deformation

2. Air cooling, not bursting

3. Precision machining, parallelism of upper and lower sides <0.003mm

Carbide mold is commonly used in the hardware machining industry because its good performance, such as high hardness, good toughness, superior high and low temperature resistance, wear resistance, low adhesion, good corrosion resistance, high thermal conductivity, low friction coefficient, acid and alkali corrosion resistance, no rust, easy maintenance, etc. Due to its good toughness, high temperature resistance and high wear resistance, the cemented carbide mold has a service life of 10 to 50 times that of a general alloy mold. Carbide molds are usually used to manufacture hard alloy stamping dies, carbide grading molds, powder pressing dies, battery shell stamping dies, stainless steel mobile phone shell stamping dies, bicycle shaft bushings, shaft bowl stamping dies, shaped carbide molds, carbide shrinkage die, carbide wire drawing die, carbide die, hard alloy thimble, carbide extrusion die, cold die of bolt and nut, frame stamping die, etc.

Technical parameters:

It is more suitable to us cemented carbide as the mold materials, especially for the molds with special application requirements. However, compared with traditional steel molds, the production and processing of cemented carbide molds requires more complete and advanced equipment and technical experience to better guarantee the precision processing. The processing of high-temperature cemented carbide molds is produced in the requirements of drawings. From the pressing and sintering of raw material blank products to the completion of precision processing of finished products, it requires a relatively long time, so customers who have the demand need to contact us in advance to ensure adequate processing time, thus avoiding delays in normal production operations.

Using high-quality materials is an effective way to improve the production efficiency. We can provide high-temperature hard alloy mold tungsten steel mold flange to meet the requirements for customs. High wear resistance is the basic requirement for die products, especially for progressive dies, combined dies and multi-station dies. The excellent performance of tungsten steel die cavity materials is the guarantee for long-term operation. As a tool material, tungsten steel has become a great choice for die products due to its high hardness, high strength and high wear resistance. We can provide non-standard customized cemented carbide die large diameter cavity according to the customer's specific drawing requirements, and the precision tolerances can meet the operation requirements. The physical parameters of conventional cemented carbide materials can be found as follows:

1. Grain size (um): 1.0 ~ 2.0

2. Cobalt content (Co%): 8.0 ~ 10

3. Density (g / cm³): 14.41- ~ 14.95

4. Hardness (HRA): 89.5 ~ 93

5. Bending strength (Mpa): 3200 ~ 4500

6. Young's modulus (Gpa): 570 ~ 620

7. Compressive strength (Mpa): 4700

If the customer has special requirements, we can provide carbide products with special requirements according to the specific conditions.

Technical paramters:

Carbide die is a high-end die commonly used in the hardware machining industry because the advantages of high hardness, good toughness, high and low temperature wear resistance, low adhesion, good corrosion resistance, high thermal conductivity, low friction coefficient, anti-acid, alkali corrosion resistance, no rust, and easy maintenance. Due to its good toughness, high temperature resistance and high wear resistance, the cemented carbide die has a service life of 10 to 50 times that of a general metal die. Carbide dies are commonly used to make cemented carbide stamping dies, carbide grading dies, powder pressing dies, battery shell stamping dies, stainless steel mobile phone shell stamping dies, bicycle shaft bushings and shaft bowl stamping dies, shaped carbide dies, carbide shrinkage die, carbide wire drawing die, carbide extrusion die, cold die of bolt and nut, frame stamping die, etc.