SIM Stable Boring Tool Holders Locking Precision with Internal Coolant Design

Application Field:

Reliable tool holder,tool bar for inner hole boring tools with internal water coolant design to improve tool lifespan. Besides,The locking pin design of the tool handle realizes efficient and repeated clamping, greatly reducing labor time costs.We can always meet your special demands due to our outstanding R&D team and standardizing factory production. Welcome to contact us!

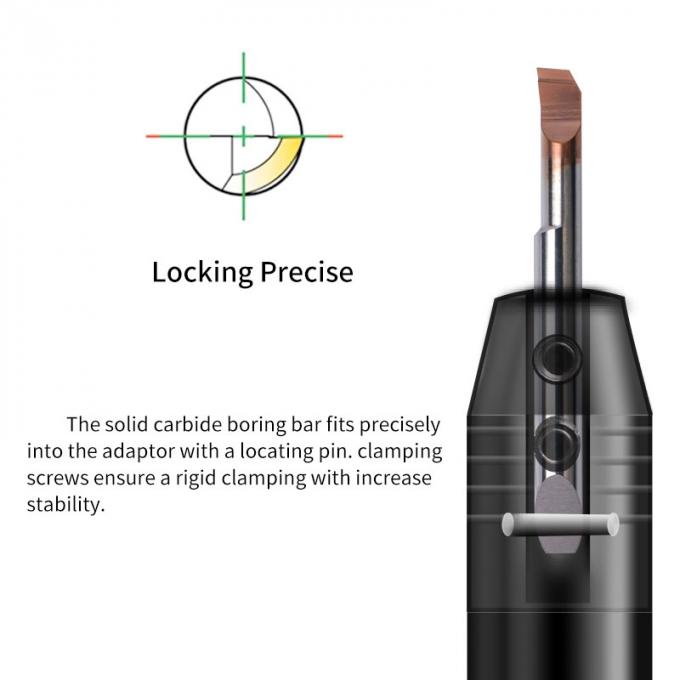

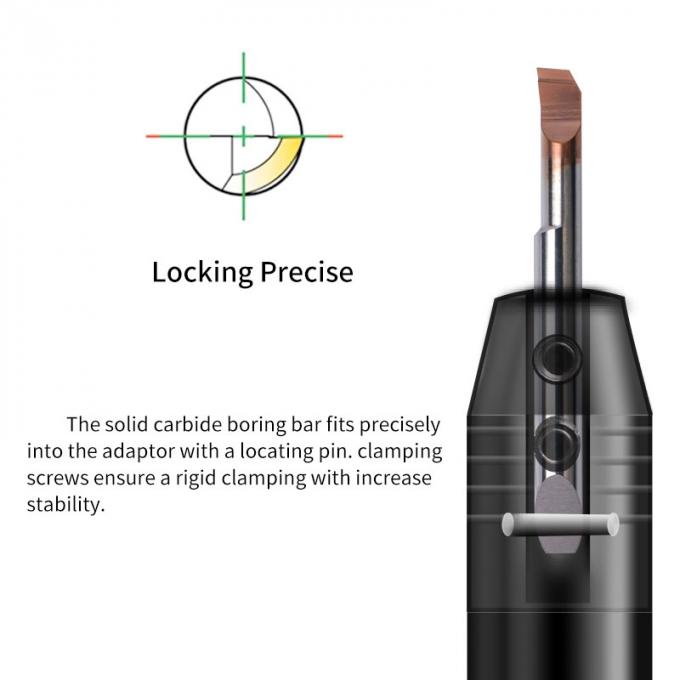

Product Details---SIM Locking Precision Holder

- Material :Steel.

- Usage:Tool holder of boring tools,mini lathe. Compatible for CNC lathes, centering machines, cutter arranging machine skateboard lathes, turret lathes and other longitudinal lathes.

- Color: Black coating.

- Small-end Diameter:4.0~7.0mm.

- Weight of item:0.20kg/pcs

- Internal coolant design: Central outlet water internal coolant design to improve tool lifespan.

Specific product information as below:

| Brand Name: | Drow |

| Model Number: | SIM boring tool-holders |

| Customized support: | OEM, ODM |

| Product type: | Locking precision Toolholders |

| Material: | Steel |

| Color: | Black coating |

| Small-end Diameter | 4.0mm-7.0mm |

| Weight of item: | 0.20kg/pcs |

| Characteristic: | Internal coolant design |

| Usage: | Tool holder of boring tools,

internal Turning Tool, CNC Machining |

| Compatible machine: | CNC lathes, centering machines, cutter arranging machine skateboard lathes, turret lathes and other longitudinal lathes |

| Mainly suitable for machine tool brands | Swiss TORNOS lathe, Citizen, Nomura, Tsugami,Star,Miyano,etc |

| Machining type | Boring and Turning |

| Customization | Professional and Available |

Product Features:

1.Taiwan Seiko, anti-shake and anti-vibration

2.Anti-seismic and anti-bending, stable performance, improve production quality and efficiency.

3.Central outlet water internal coolant

4.Precision ground high-quality tool steel, high temperature quenching, good toughnes

5. The locking pin design of the tool handle realizes efficient and repeated clamping, greatly reducing labor time costs

Product Specification

| Model | D | D1 | L | h | Clamping Screw |

| SIM0012-D4 | 12 | 4.0 | 75 | 11 | T0507 |

| SIM0012-D5 | 12 | 5.0 | 75 | 11 | T0507 |

| SIM0012-D6 | 12 | 6.0 | 75 | 11 | T0507 |

| SIM0016-D4 | 16 | 4.0 | 75 | 14 | _T0507 |

| SIM0016-D5 | 16 | 5.0 | 75 | 14 | T0507 |

| SIM0016-D6 | 16 | 6.0 | 75 | 14 | T0507 |

| SIM0016-D7 | 16 | 7.0 | 75 | 14 | T0507 |

| SIM0020-D4 | 20 | 4.0 | 90 | 18 | T0507 |

| SIM0020-D5 | 20 | 5.0 | 90 | 18 | T0507 |

| SIM0020-D6 | 20 | 6.0 | 90 | 18 | T0507 |

| SIM0020-D7 | 20 | 7.0 | 90 | 18 | T0507 |

| SIM0022-D4 | 22 | 4.0 | 90 | 20 | T0507 |

| SIM0O22-D5 | 22 | 5.0 | 90 | 20 | T0507 |

| SIM0022-D6 | 22 | 6.0 | 90 | 20 | T0507 |

| SIM0022-D7 | 22 | 70 | 90 | 20 | T0507 |

| SM0025-D4 | 25 | 4.0 | 90 | 23 | T0507 |

| SIM0025-D5 | 25 | 5.0 | 90 | 23 | T0507 |

| SIM0025-D6 | 25 | 6.0 | 90 | 23 | T0507 |

| SIM0025-D7 | 25 | 7.0 | 90 | 23 | T0507 |

| SIM1000-D4 | 25,4 | 4.0 | 90 | 23.4 | T0507 |

| SIM1000-D5 | 25.4 | 5.0 | 90 | 23.4 | T0507 |

| SIM1000-D6 | 25.4 | 6.0 | 90 | 23.4 | T0507 |

| SIM1000-D7 | 25.4 | 7.0 | 90 | 23.4 | T0507 |

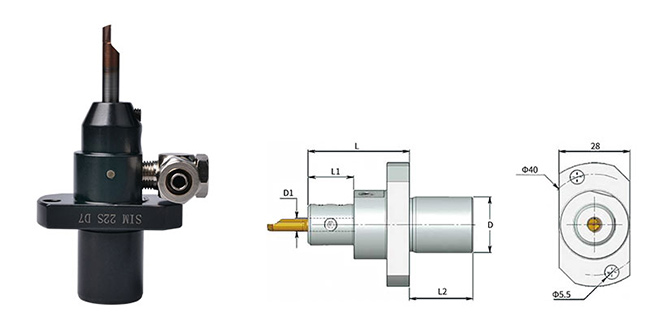

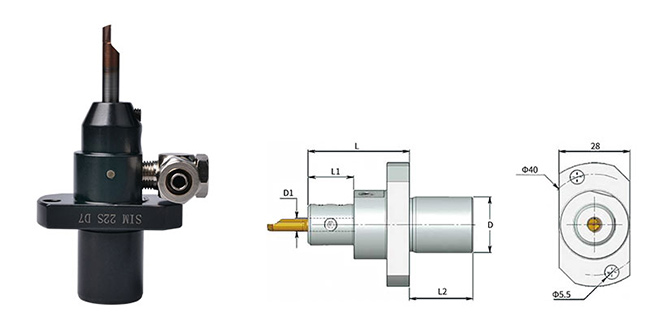

| Model | D | D1 | L | L1 | L2 | dp Water hole pipe | Clamping Screw |

| SIM22S-D4 | 22 | 4.0 | 52 | 30 | 25 | 6.0 | T0507 |

| SIM22S-D5 | 22 | 5.0 | 52 | 30 | 25 | 6.0 | T0507 |

| SIM22S-D6 | 22 | 6.0 | 52 | 30 | 25 | 6.0 | T0507 |

| SIM22S-D7 | 22 | 7.0 | 52 | 30 | 25 | 6.0 | T0507 |

Product Show

Rigorous Quality Inspection

1.Projector detection

2.ZOLLER detection

3.Swis edging

4.German forging difference process detection

5.Edge passivation detection

6.Coreless grinding

Why choose us:

1.Advanced Technology: Complex surfaces and functional structures can be quickly formed and kept accurate.

2.Short Machining Period: Short production cycle to ensure delivery on time according to the delivery date.

3.Crowned Product: High quality guaranteed.High precision, up to 0.005-0.001mm.

4.Confidentiality System: Triple confidentiality measures to protect customer’s private design. Proofing more assured.

5.Fully Equipment: Excellent processing capacity, multiple production lines, advanced equipment, professional supporting facilities.

6.Cost-effective: Reasonable design and material selection lead us to a competitive price, so that could help supply customers cheaper price of the same level products .

FAQ

Q1:If we want to cooperate with you, is it possible to get confidentiality?

A: Sure, all your information including company info, drawings, PO details will be kept confidential, we can signed NDA if you want (non disclosure agreement).

Q2: What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3: How can we trust your product quality?

A: 100% products quality inspection for first batch, and casual inspection for the coming batch.Raw material will be tested before bulk production and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping

Q4: What else can you buy from us?

A: Carbide insert,carbide end mill,carbide drill,carbide boring,cutting tools&customized carbide precision molds.

Q5: Can we get a discount if our ordered quantity is big enough ?

A: Yes. If your ordered quantity is big enough , we can offer you our best price and will give you a discount.

Q6. Could you offer OEM and ODM service?

A:It’s okay , we have more than 10 years experience in OEM service.Our professional R&D team is dedicated to design products to fit various demands of customers. They can always offer the professional advice and solutions for you!