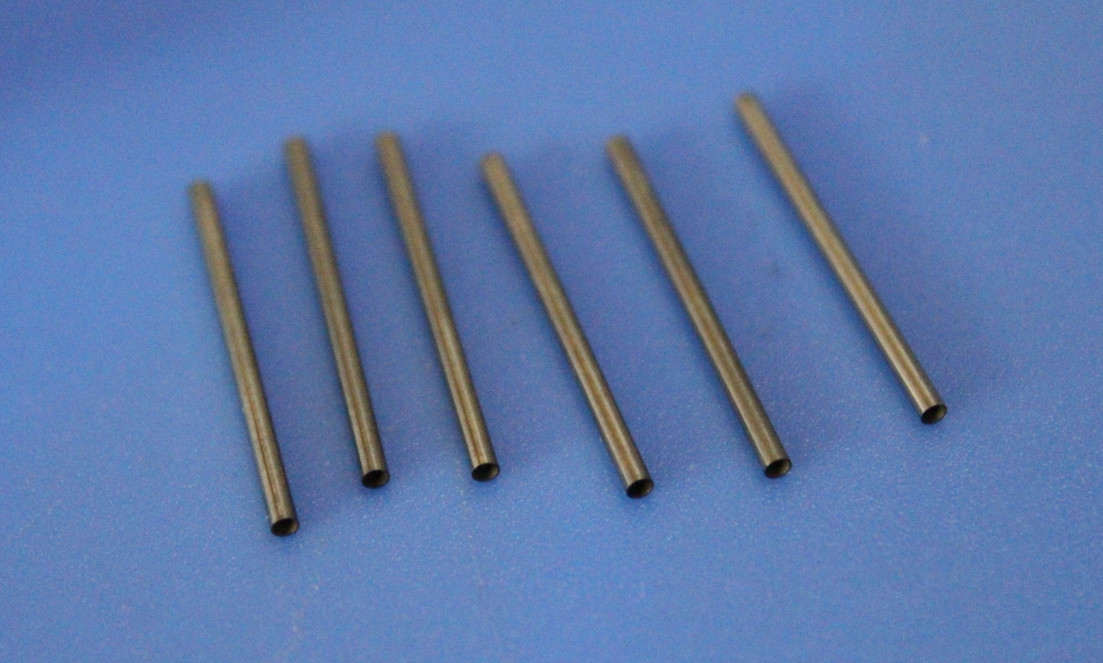

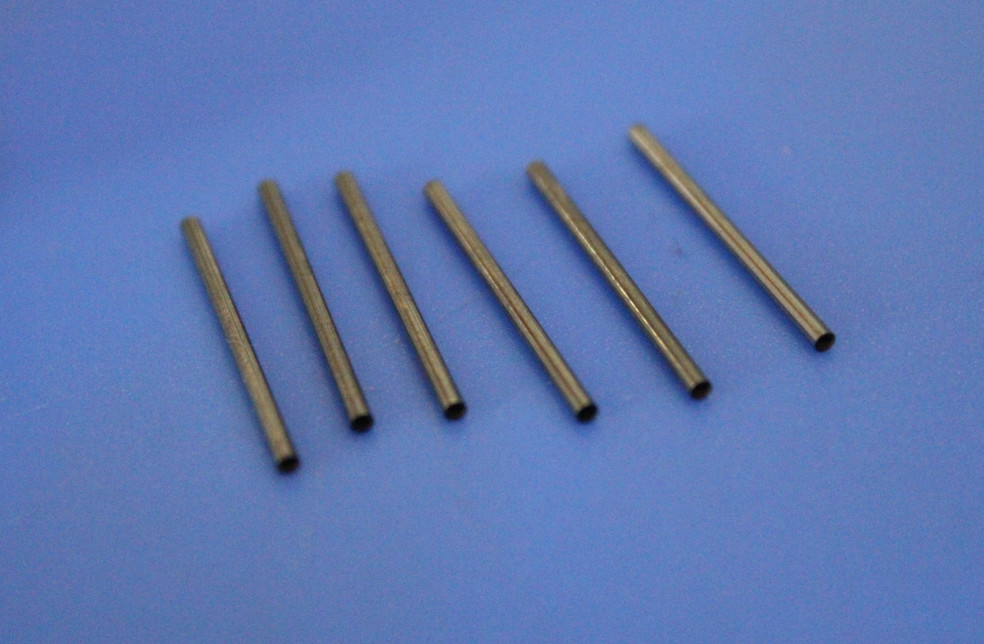

Seat Oil Valve Head Tungsten Carbide Sleeve For Processing Sealing Operation

introduction

Tungsten steel valve seat petroleum valve head, Zhuzhou Sanxin Cemented Carbide Production Co., Ltd. produces and processes tungsten steel oil valve seat valve head, which is specialized in oil production and processing sealing operation.

Carbide valve seat tungsten steel petroleum valve head, Zhuzhou Sanxin hard alloy production tungsten steel processing non-standard custom oil valve seat, petroleum valve ball, petroleum valve pair and other series of wear-resistant, corrosion-resistant oil use equipment requirements hard Alloy parts tungsten steel fittings. Tungsten steel valve seat, valve pair or carbide ball valve is evolved from the traditional plug valve. The opening and closing member is a ball, which is opened and closed by the ball around the axis of the valve stem. The main function of the carbide ball in the pipeline is to cut off, distribute and change the direction of the medium flow. The ball valve designed into other special structures can also realize the function of flow regulation. The high-precision custom-made tungsten steel valve sub-ball valve ball seat is used in oil drilling, deep-sea drilling pumping ball, ball seat, which is a key part of the pump. The use of valve seat oil valve heads is mainly based on the production of petroleum equipment.

| Name: | Tungsten Carbide Sleeve | Pin Ceramic Nozzle: | Costum |

|---|

| Tungsten Steel Slider Insert Head: | Costum | Type: | Tungsten Steel Mold Production And Processing |

|---|

| Model: | Tungsten Steel Mold | Tungsten Steel Pin: | Processing Sealing Operation |

|---|

Advantage

As one of the main targets of geological exploration, petroleum is a viscous, dark brown liquid called "industrial blood". It is a non-renewable raw material. The more scientific and effective oil exploitation process is also the socio-economic development. Inevitable requirements. In the process of oil exploitation and transportation, the failure modes of the pump ball of the pump mainly include wear, corrosion, fatigue cracks, collapse and other reasons, which make the valve ball materials (such as bearing steel, ceramics, etc.) used in oil drilling in the past. Early failure occurs, which shortens its service life. For example, bearing steel is easily corroded by liquid and wear resistance is poor. Ceramics are brittle materials with poor impact toughness and are prone to chipping. The high hardness, high density, high strength and stable chemical properties of cemented carbide and its good flexural strength, impact toughness make the use of tungsten steel valve seat head on the upgraded oil drilling oil pump exceeds other material choices. Excellent wear and corrosion resistance greatly improves drilling efficiency, extends tool life and reduces operating costs.

Our Service

With the requirements of social and economic development and the increasing progress of science and technology, the improvement of the performance of tool materials is an effective form to improve production efficiency. Carbide seat, petroleum valve head, carbide valve pair, carbide ball valve seat will be used more and more, the types and quantities continue to increase, and towards high temperature and high pressure, high sealing, large diameter, easy Adjustment, long service life and the development of a multi-function valve. Its reliability and comprehensive performance have reached a high level, which will replace some of the gate valve, regulating valve and globe valve. In addition to the innovation of cemented carbide ball valve technology, it will be used in industrial scale production such as oil and gas pipelines and refinery crackers.