Introduction:

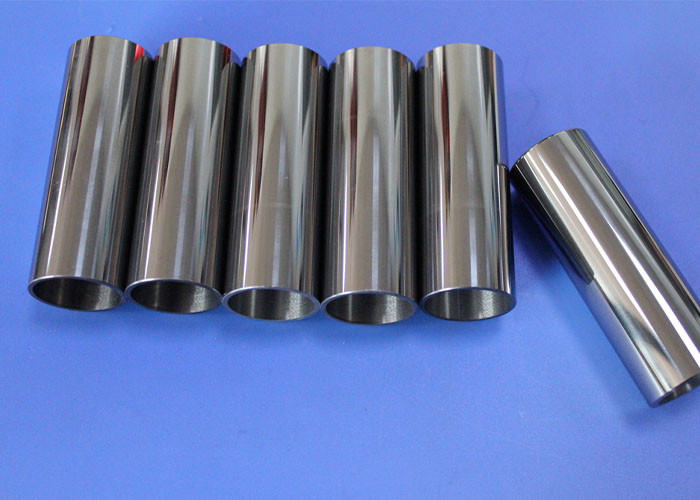

We produce non-standard customized die inserts, which are used for secondary stretching of 15F outer casing parts of auto parts. It is manufactured according to the drawings of customers' auto parts.

Compared to other metal steel dies, tungsten steel drawing dies have better wear resistance, longer service life, better smoothness and higher production efficiency. In particular, the tungsten steel die inserts processed have better performance in the outer casing stretching of the automobile parts. The automobile casing tungsten steel drawing die is made up of coarse-grained tungsten steel material, which has good bending strength for stretching work. And its physical hardness performance can ensure the long-lasting wear resistance of the stretching operation. According to the drawings and requirements of auto parts manufacturing and processing, the overall specification size is: φ162.6*φ128*φ114.6*60.

Technical parameters:

The automobile casing tungsten steel drawing die is produced and processed according to the requirements of auto parts customers in Liaoning province. The main customers of the auto parts company include Liaoning Huachen Dongxing Auto Parts Co., Ltd., Liaoning Fuda Auto Parts Co., Ltd., Liaoning Bolinte Elevator Co., Ltd., Hebei Great Wall Motor Co., Ltd., Liaoning Shuangfu Machinery Co., Ltd. Zoomlion Group, North Heavy Industry Group Automobile Steering Branch, etc. The manufacturing industry is the foundation of the national economy. According to the actual working requirements and drawing parameters of the 15F outer casing, the surface roughness is 0.2. There are 6 M8 threaded holes on the back for easy assembly. Due to long time of production and processing of the whole tungsten steel die and relatively cumbersome precision machining process, we need enough production time to ensure the dimensional accuracy. The detailed drawing is as follow