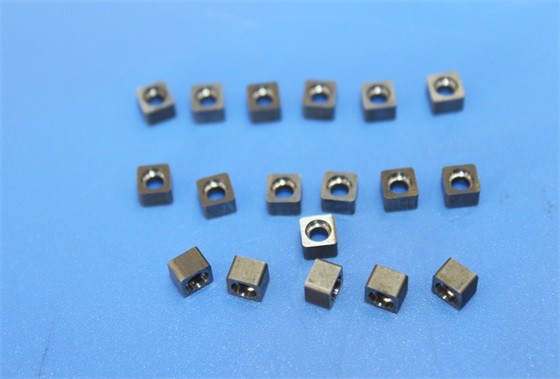

Shaft Tungsten Carbide Bushing / OEM Hard Alloy Metal Bearing Bushing

Steel Pipe Sleeve Introduction:

Tungsten carbide bushing set up by virgin tungsten carbide material. It’s shows high hardness and bending strength. That has superior performance on resisting abrasion and corrosion, which is widely used in many industries

For its widely usage. Tungsten carbide bushing are often made with high accuracy, and owing to their perfect finish, precise dimension, durability and corrosion resistance. These are highly appreciated by the clients at home and aboard.

In addition, differ from the various of application environment. There are several types of Tungsten carbide bushing. Most of the specifications are all customized. Zhuzhou Tongda Carbide has backed by rich industry knowledge and production experience of various Tungsten carbide bushing. This can produce various of Tungsten carbide bushing based on specific design.

Conventional cemented carbide mold products are weakly magnetic. The non-magnetic hard alloy molds require customized production and processing. The magnetic ring rotor upper cavity used in the AR-8 magnetic ring rotor mold requires non-magnetic carbide mold. Non-magnetic cemented carbide refers to hard alloy material that is not magnetic. The molding die for production of magnetic materials requires to use non-magnetic materials. In the past, non-magnetic steel has been used to manufacture mold, which mold performance is poor, the hardness is low, the service life is short, and the inner wall of the mold is severely pulled and deformed after a period of use. All these affect the dimensional accuracy and surface quality. The non-magnetic hard alloys, with its excellent performance, can effectively improve production efficiency.

| Name: | Tungsten Carbide Bushing | Pin Ceramic Nozzle: | Costum |

|---|

| Tungsten Steel Slider Insert Head: | Costum | Feature: | Wear Resistance |

|---|

| Size: | Customized | Other Name: | Hard Alloy Metal Bearing Bushing |

|---|

Steel Pipe Sleeve Advantages:

Carbide materials and molds are provided according to customer's specific requirements. As a cemented carbide production and processing manufacturer in Zhuzhou, we have been committed to providing precision tungsten steel products for the mechanical industry production. The accuracy tolerance of the tungsten carbide machining can be ±0.002.