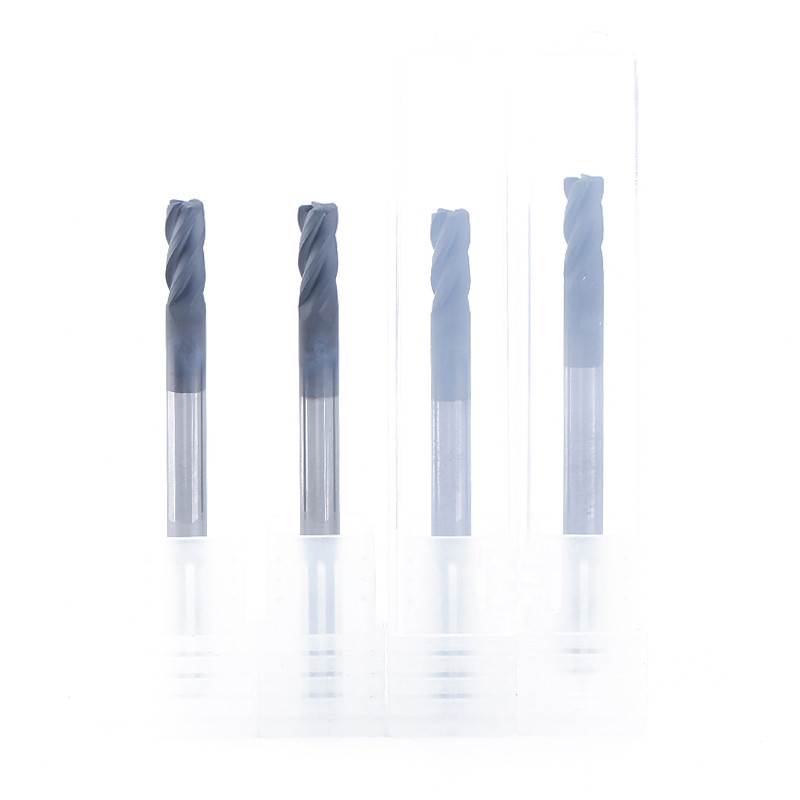

Solid Carbide Internal Thread End Mill 3-teeth Milling Cutters for Metal Milling

Application Field:

Solid tungsten carbide internal thread milling cutters are mainly used for metal internal threading&milling which is suitable for machining carbon steel, iron steel, low and high alloyed steel and so on. With advanced nanometer coating on flutes, this cutter provides predictable and long tool life in a range of applications, including rough machining and finishing processing.

Besides, your particular demands will always be met due to our outstanding R&D team and standardizing factory production. Welcome to contact us!

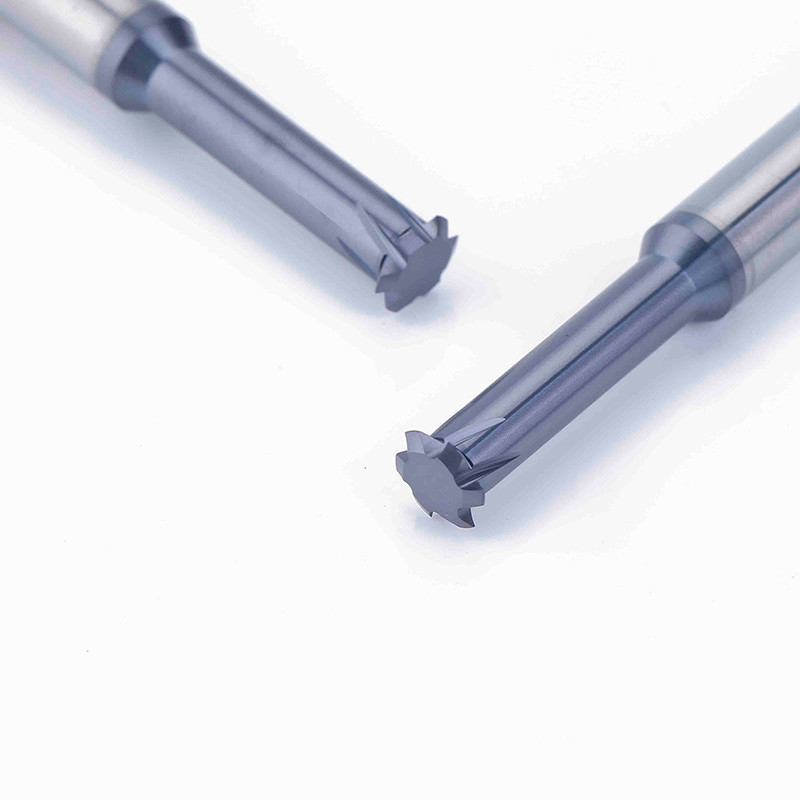

Product Details--3-teeth Milling Thread Cutters

- Material :Tungsten Carbide, 100% New Material with high wear resistance and hardness.

- Usage:Internal thread milling,suitable for all kinds metal,plastic,wood,Acrylic and so on. Compatible For CNC machining center, engraving machine and other high-speed machines.

- Hardness: HRC 45/55/60/65 Degrees.

- Specification:3T,M1.0~M24

- Shank Diameter:4~16mm

- Coating : AlTiN /TiAlN /TiSiN /NaCo /DLC /Diamond. Various coating can always support your diverse application field.

- Grinding process: Introducing mirror grinding technology,leads your machining product to high precision.

- Chip removal design: Large-capacity chip flutes design, improve your production efficiency.

Specific product information as below:

| Brand Name: | Drow |

| Model Number: | Three-teeth Internal Thread Milling Cutter |

| Customized support: | OEM, ODM, OBM. |

| Standard: | ISO |

| Product type: | Milling Thread Cutter |

| Material: | Tungsten Carbide, 100% New Materia |

| Coating: | AlTiN /TiAlN /TiSiN /NaCo /DLC, per your demands |

| Hardness: | HRC 45/55/60/65 Degrees |

| Specification: | M1.0~M24 |

| Shank Diameter: | 4~16mm |

| Sample Order: | Accepted |

| Usage: | Internal Thread Milling |

| Applicable Material: | Stainless steel, cast iron, carbon steel, quenched steel and so on |

| Compatible machine: | CNC machining center, engraving machine and other high-speed machines. |

| Machining type: | Roughing / Semi-Finishing/Finishing |

| Customization: | Professional and available,meet your special requirement |

Product Features:

1.100% New Material: The material is high carbon steel, after quenching, it has high hardness,good wear resistance and durable.

2.High density coating process: Leads to excellent wear resistance and effective heat insulation to ensure a long service life of the tool.

3.Large core diameter design: Arc cutting edge, large core diameter design,wear-resistant high-strength anti-bending

4.Burr-free cutting:The cutting edge is sharp and wear-resistant,has the characteristics of good chip removal,high processing efficiency,precise thread and high durability

5.Sharp and precise:Using mirror grinding technology,combined with large-capacity chip flutes,sharp and precise

6.Universal round shank: External grinding and step difference 1u roundness,2u straightness, to achieve minimal runou

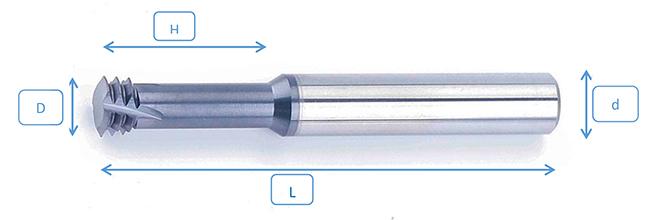

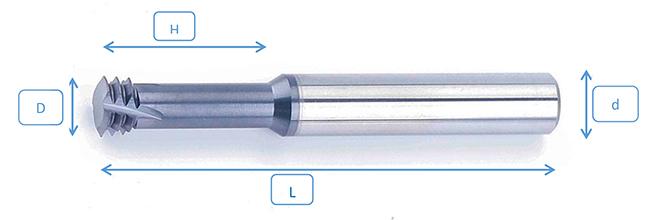

Product Specification:

| Model | Pitch | Shank Diameter | Cutting Diameter | Cutting Length | Total Length | Flutes |

| mm | d mm | D mm | H mm | L mm |

| M1.0x0.25 | 0.25 | 4 | 0.73 | 2.3 | 50 | 3 |

| M1.2x0.25 | 0.25 | 4 | 0.92 | 2.8 | 50 | 3 |

| M1.4x0.3 | 0.3 | 4 | 1.05 | 3.2 | 50 | 3 |

| M1, 6x0 .35 | 0.35 | 4 | 1.2 | 3.3 | 50 | 3 |

| M1.8x0.35 | 0. 35 | 4 | 1..41 | 4.1 | 50 | 3 |

| M2.0x0.4 | 0.4 | 4 | 1.54 | 4.4 | 50 | 3 |

| M2.2x0. 45 | 0. 45 | 4 | 1. 63 | 4.8 | 50 | 3 |

| M2.5x0 45 | 0.45 | 4 | 1,96 | 5.3 | 50 | 3 |

| M3x0.5 | 0.5 | 4 | 2.4 | 6.4 | 50 | 3 |

| M3.5x0.6 | 0.6 | 4 | 2.75 | 7.4 | 50 | 3 |

| M4x0.7 | 0.7 | 4 | 3.15 | 8.6 | 50 | 3 |

| M4.5x0.75 | 0.75 | 4 | 3.5 | 9.5 | 50 | 3 |

| M5x0.8 | 0.8 | 6 | 4 | 12 | 50 | 3 |

| M6x1.0 | 1 | 6 | 4.75 | 13 | 50 | 3 |

| M8x1.25 | 1.25 | 6 | 6 | 17.3 | 50 | 3 |

| M10x1.5 | 1.5 | 8 | 8 | 21.8 | 60 | 3 |

| M12x1.75 | 1.75 | 10 | 10 | 24 | 75 | 4 |

| M14x2.0 | 2 | 10 | 10 | 25 | 75 | 4 |

| M16x2.0 | 2 | 12 | 11.5 | 27 | 75 | 4 |

| M20x2.5 | 2.5 | 16 | 15 | 36 | 90 | 4 |

| M4x0.5 | 0.5 | 4 | 3 | 8.6 | 50 | 3 |

| M6x0.75 | 0.75 | 6 | 4.8 | 13 | 50 | 3 |

| M8X1.0 | 1 | 6 | 6 | 17.3 | 50 | 3 |

| M8x0.75 | 0.75 | 6 | 6 | 17.3 | 50 | 3 |

| M8x0.5 | 0.5 | 6 | 6 | 17.3 | 50 | 3 |

| M10x1.25 | 1.25 | 8 | 8 | 21.8 | 60 | 3 |

| M10x1.0 | 1 | 8 | 8 | 21,.8 | 60 | 3 |

| M10x0.75 | 0.75 | 8 | 8 | 21.8 | 60 | 3 |

| M10x0.5 | 0.5 | 8 | 8 | 21.8 | 60 | 3 |

| M12x1.5 | 1.5 | 10 | 10 | 25 | 75 | 4 |

| M12x1.25 | 1.25 | 10 | 10 | 25 | 75 | 4 |

| M12x1.0 | 1.0 | 10 | 10 | 25 | 75 | 4 |

| M14x1.5 | 1.5 | 10 | 10 | 28 | 75 | 4 |

| M14x1.25 | 1.25 | 10 | 10 | 28 | 75 | 4 |

| M14x1.0 | 1 | 10 | 10 | 28 | 75 | 4 |

| M16x1.5 | 1.5 | 12 | 12 | 30 | 75 | 4 |

| M16x1.25 | 1.25 | 12 | 12 | 30 | 75 | 4 |

| M16x1.0 | 1 | 12 | 12 | 30 | 75 | 4 |

| M20x2.0 | 2 | 16 | 15.8 | 40 | 90 | 4 |

| M20x1.5 | 1.5 | 16 | 15.8 | 40 | 90 | 4 |

| M20x1.0 | 1 | 16 | 15.8 | 40 | 90 | 4 |

| M24x3.0 | 3 | 16 | 16 | 45 | 90 | 4 |

Why choose us:

1.Technical innovation: complex surfaces and functional structures can be quickly formed and kept accurate.

2.Processing speed: short production cycle, fast delivery time, to ensure delivery on time according to the delivery date.

3.Product quality:Absolutely strict inspection. high quality guaranteed,high precision, up to 0.002-0.001mm.

4.Confidentiality system: triple confidentiality measures to protect, proofing more assured.

5.Fully equipped: excellent processing capacity, multiple production lines, advanced equipment, professional supporting facilities.

6.Cost-effective: reasonable design and material selection lead us to a competitive price, so that could help provide you more favorable price of the same level products .

FAQ

Q1: how can we guarantee quality?

A: Always a pre-production sample before mass production;Always final Inspection before shipment;

Q2: what can you buy from us?

A: Carbide insert,carbide end mill,carbide drill,carbide boring,cutting tools&customized carbide precision molds

Q3:why should you buy from us not from other suppliers?

A: We Drow devote ourselves in research and development of tungsten carbide, cutting tools, cutting inserts, and new materials, specializing in the design and production of carbide turning inserts , indexable inserts, CNC inserts etc.

Q4: What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.