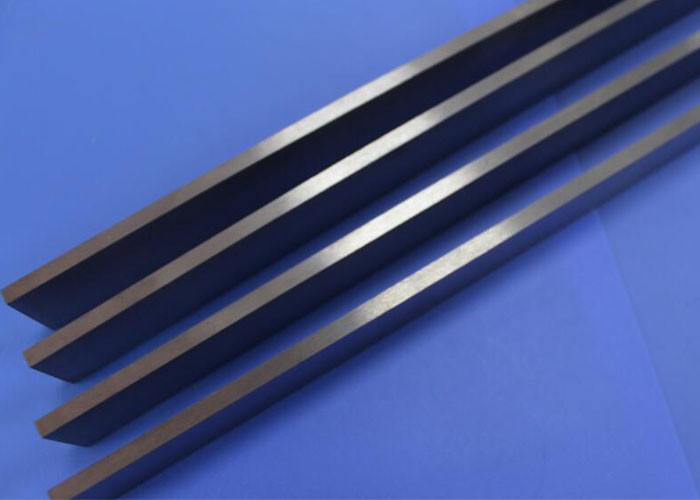

Special Customized Precision Carbide Mold Punch Pins And Dies Stamping

Introduction:

Product Name | Special Customized Precision Carbide Mold Punch Pins And Dies Stamping |

Material | Tungsten carbide |

Grade | Tungsten carbide/White steel,etc. |

Size | Customized |

Thread | polishing,coating and many more |

Processing object | Stainless steel, aluminum alloy, copper alloy, cast iron and more |

Used | Stamping, stretching, drawing, forging |

In order to improve the production competitiveness, the metal products industry pays more and more attention to the quality of the drawing die and the improvement of the manufacturing process. The research of improving the service life, the material, structure, manufacturing process, manufacturing equipment and inspection and removal instruments of the wire drawing die, new composite drawing die, new drawing die material, new surface coating technology and new hole design method have been developed, which has promoted the development of the world's wire drawing production. China is a big wire producer and its output ranks among the top in the world. China's mold manufacturing has developed rapidly since the 1980s. With the continuous improvement of the wire drawing mold manufacturing level and the production technology, China's mold manufacturing has developed a lot, especially with great improvements of the material selection and structure forming. But there is still a big gap with foreign countries. Although the types of wire drawing molds are similar, the materials and processing technology used are more advanced. Thus, the processing precision, durability and wear resistance are superior to those of our products. Therefore, strengthening the mold management, improving the quality level and promoting the advancement of the mold-making technology are the important issues currently faced by the molding industry.

Technical parameters:

The microstructure of the TICN coating of fine Nano particles combines the advantages of high toughness, high hardness, high oxidation resistance, and can reach extremely lubricious surface with frictionless chip evacuation. Thus, the workpiece has great performance. After TIN coating treatment, mold has the advantages of good surface brightness, small friction coefficient, high hardness and strong oxidation resistance. For different molds (powder metallurgy mold, stamping mold, forming mold, stretching mold, forging die, etc.) using different coating technology can improve the performance of the extreme parts, like the hardness, wear resistance, corrosion resistance, heat resistance and smoothness of the appearance are greatly improved. It can also be used as release film to enhance the quality (such as appearance roughness, precision, etc.) and prolong the service life of molds. Thus, it can effectively realize the excellent performance of the product.

Advantages:

Advantage 1: Reduce friction coefficient, reduce processing stress, improve appearance hardness, greatly extend mold service life, avoid product galling and straining, improve product quality, save the trouble of unloading, polishing and reloading and improve efficiency

Advantage 2: There are early malfunctions during using. The factors are usually abrasive wear, corrosion, blending, adhesion, and the like. These problems not only to reduce the working time, but also greatly increase the cost of consumption, which in turn affects the competitiveness of enterprises. Many manufacturers have though of different treatments, and the titanium-plated surface treatment technology is an effective plan to deal with the above problems. PVD coating technology is widely used to all kinds of tools, molds, mechanical parts, medical equipment, etc. that is caused by wear, occlusion, corrosion, adhesion, blending, etc. by using this technology, the malfunction caused by abrasion (such as: blanking, cold heading, powder molding, etc.) can be improved the service life of the product by more than 5-8 times. And the bite caused or the mold pulled (such as: extension die, drawing die, flanging die, etc.) can be used again after the coating.