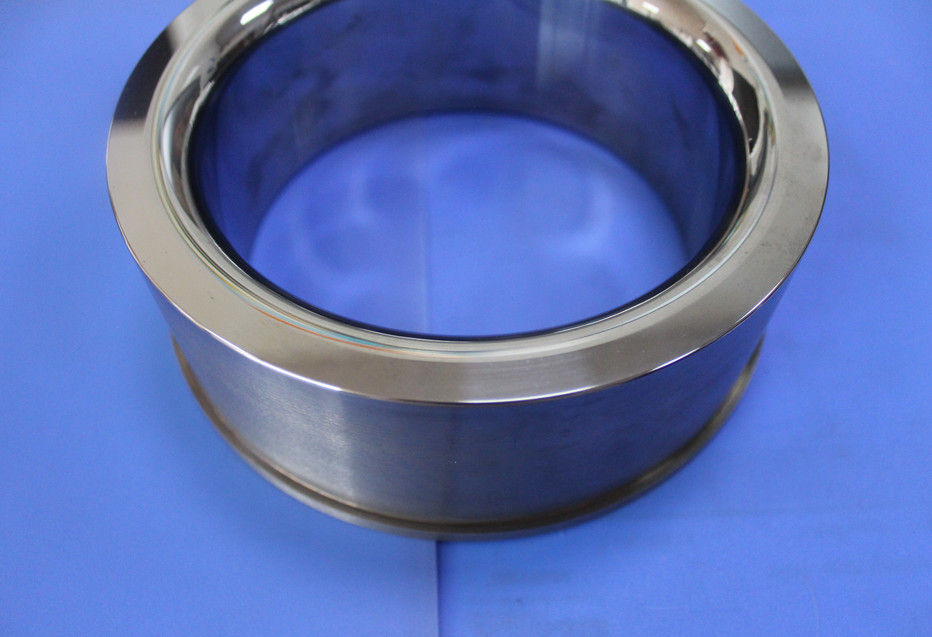

Customized Tungsten Carbide Mold Cememted Carbide Wire Drawing Mold

Zhuzhou Sanxin Cemented Carbide Manufacturing Co., Ltd.

Located at No.8 Zhongxue Road, Baiguan Town, Lusong District, Zhuzhou 412102, Hunan, China.

It's a reliable and professional wolfram carbide nozzles, spray head parts manufacture with custom services.

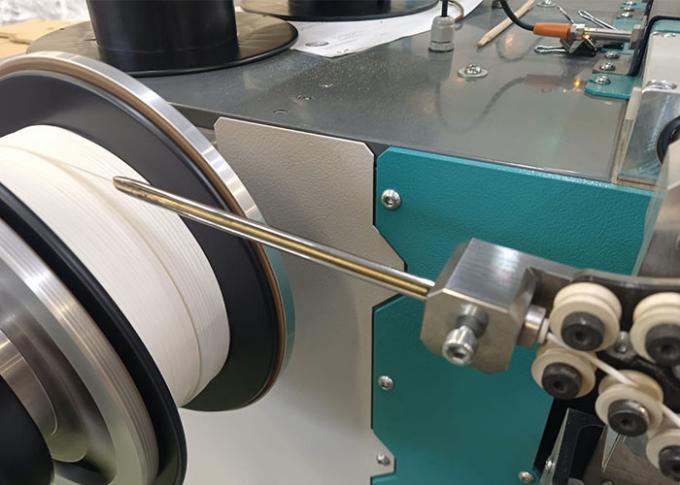

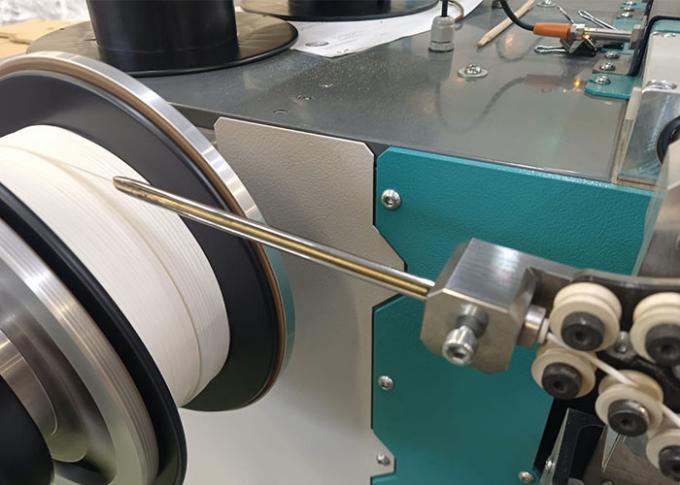

This drawing die, is a mold for punching, blanking, bending modulus of the composite structure design and principle.

Also a tool for designing a set bore falling anticipating,checking elements with materials with carbon fiber to check resistance

Blank punched hole compound model characteristic is that availability is high.

Mostly used by its piercing, wear resistant, long service life and stable quality.

Using the tool carrier within the dumping bodies to facilitate loading materials, and to improve accuracy.

Key Points:

| Carbide Grade | YG8, YG10, YG15, G10, K30, K40, etc |

| Raw Material | 100% virgin tungsten carbide powder, quality Cobalt powder. |

| Processing | Sintering, Grinding, Polishinig, etc. |

| Replacement | Can be replaced |

| Requirement | Good impact resistance and wear resistance |

| Other Grade | Density(g/cm3) | Hardness(HRA) | MPa |

| KZ40C | 13.30~13.45 | 87.0~88.0 | ≥3000 |

| KZ30A | 14.03~14.17 | 88.0~89.0 | ≥3000 |

| KZ35 | 13.85~14.04 | 87.5~88.9 | ≥2800 |

| YG20 | 13.45~13.65 | ≥84.5 | ≥2480 |

| YG15 | 13.95~14.15 | ≥86.5 | ≥2400 |

| YG16C | 13.75~13.95 | ≥84.0 | ≥2640 |

| YG13C | 14.15~14.35 | ≥85.5 | ≥2450 |

Basic properties:

1. High hardness and high wear resistance

2. High elastic modulus

3. High compressive strength

4. Good chemical stability (acid and alkali corrosion, high temperature oxidation)

5. Low impact toughness

6. Low expansion coefficient. The thermal conductivity and electrical conductivity is similar to iron and its alloys.

Real producing factory view provided.