Introduction:

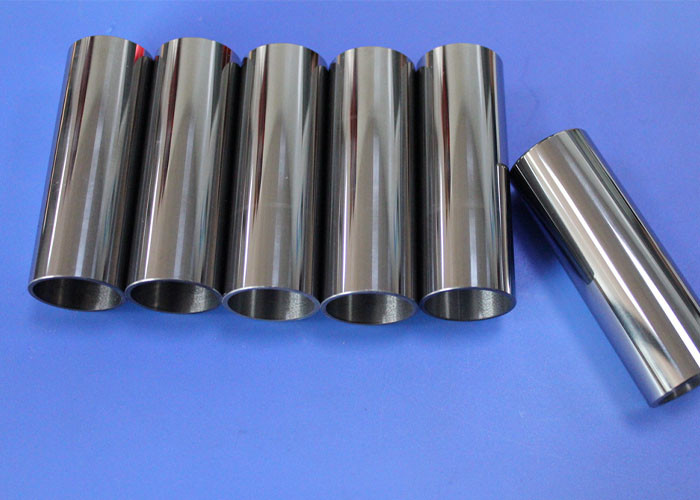

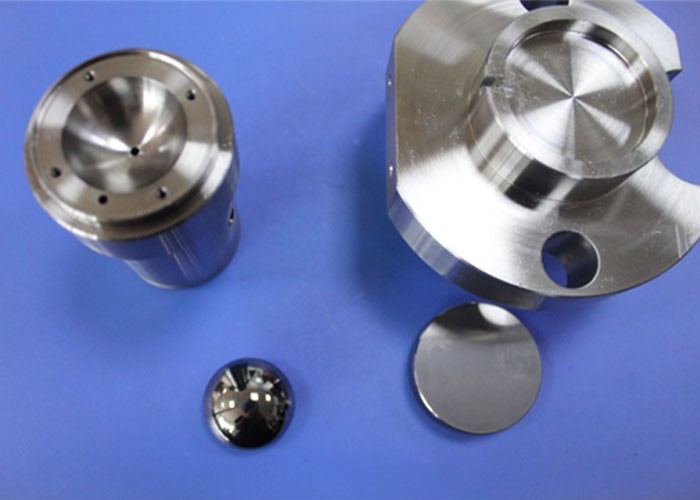

For matching requirements, we can provide a series of customized tungsten steel precision die parts and accessories,such as fixed die inserts, movable die inserts, slider inserts, mold inserts, etc.

The die is a major equipment in industrial production. As an important means of industrial production, the development of modern industrial products and the technical level depend to a large extent on the development of the die industry. The service requirements for precision die parts and accessories will directly affect the production efficiency of die products. As the industrial tooth, cemented carbide has the advantages of high hardness, high strength, strong physical stability and good wear resistance. It is a good choice for die parts, especially for tungsten steel parts die slider insert, which requires ultra-high precision dimension for the die fittings.

As a cemented carbide production and processing factory, relying on the cemented carbide production technology and industry chain in Zhuzhou and depending on the professional equipment and rich experience, we provide customers with high-quality cemented carbide die parts and non-standard shaped tungsten steel wear resistant parts. Based on customer's drawings, we use high-quality materials to meet the application requirements of tungsten steel die parts.

Technical parameters:

The dimensional accuracy tolerance of die slider inserts is ±0.0005. Each manufacturing procedure is strictly in accordance with customer’s drawings to meet the performance of operation.

Advantages:

The precision of tungsten steel die parts is μ level. To achieve μ-level precision tolerance, this requires strong technical support, rich experience and professional production equipment with tungsten steel deep processing systems. In particular, the tolerance requirements of precision die parts are required to meet the overall accuracy requirements.

After-sales service:

we can provide a series of customized tungsten steel precision parts and accessories, such as fixed die inserts, movable die inserts, slider inserts, mold inserts, etc.

Welcome to contact us!