Tungsten Carbide Molds For Forging,Fastening,Spring,Bearing,Drawing,Roller Etc

Application Field:

Tungsten Carbide widely used in molds and dies. Classify as below:

| Classification | Application |

| Forging Die | Forging molds for automotive components processed by hot forging, cold forging. and precision forging process. |

| Fastening Die | Fastening products for automotive, construction, home appliance, aerospace and other industries. |

| Spring Tool | Tool for precision process spring which is used in automotive and high-end electronic products. |

| Bearing Tool | Tool for process bearing products, which include the forming of bearing ball, bearing wheel and ring. |

| Powder Metallurgy Die | Various precision gear parts for automotive, motorcycles and electronic products. |

| Roller | Various roller products for wire forming and fronts portion of production. |

| Drawing Die | Tools apply in the diameter reduction and forming of wire and tube. |

| Optical Mold | High precision mold for the photo voltaic industry, which apply in processing aspherical glass lens for mobile phone, camera security monitoring. |

| Can Making | Tools for seamless tin forming, provide solution for processing of punching, stretching and retracting. |

Product Details--- Carbide Drawing Dies

1.Surface Roughness:RZ~~0.2um / F1.0mm/min

2.Accuracy: ±0.001mm

3.Customization: Absolutely customization. There is no standard stock for this series of products, and only non-standard orders are accepted. Please attach CAD drawings/3D drawings to your inquiry, thank you.

4.Material:Virgin tungsten carbide add Co elements, properties as below:

| Material | Material Properties |

| carbide: | Cemented carbide is a powder metallurgical composite consisting of one more hard material phases (e.g. tungsten carbide) and a binding material (e.g. cobalt). It is an extremely hard material, characterised by high wear resistance an thermal stability. It is used in various fields that require tools or components to be particularly wear-resistant.Compared to die steel, it is more difficult to machine and has a higher material cost, but its service life is often several times longer than that of die steel. |

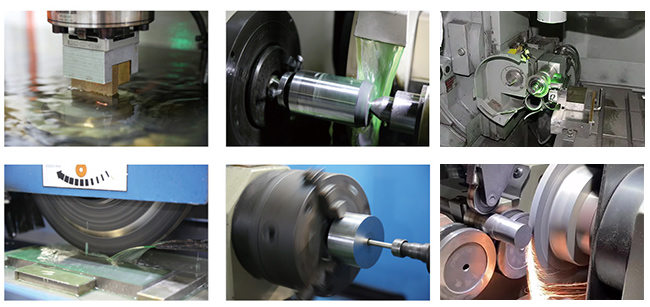

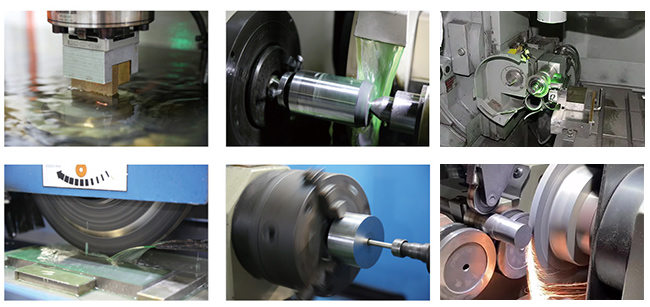

Involve Machining Technology:

- Involve Production Technology: Cylindrical grinding, internal circular grinding, optical profile grinding, flat grinding, thread machining, middle speed wire cutting, low speed wire cutting, mirror discharge machining and so on.

Why choose us:

1.Advanced Technology: Complex shapes and various structures can be quickly formed and kept precise.

2.Efficient Processing: Short production cycle and rapid delivery, to ensure shipment schedule according to the delivery date.

3.Product quality: Consistent quality guaranteed.High accuracy, up to ±0.003mm.

4.Confidentiality system: Triple confidentiality measures to protect .If you need, we can sign a NDA(Non Disclosure Agreement), proofing more assured.

5.High-end and fully equipped: Outstanding processing capacity, multiple production lines, advanced equipment, professional supporting facilities.

6.Cost-effective: Reasonable design and material selection lead us to a competitive price, so that could help offer you more favorable price of the same level products .

Kinyet focuses on tungsten relevant material research and development all the time. Through constantly introducing new technology and increase investing on high-end production equipment, Kinyet is able to offer molds solution with high-quality-price-ratio, include high precision,higher tooling life and cost effective etc. Now Kinyet is merged with IsCarbide. With this powerful combination, believe we will create more excellent products for consumer in the future!

Quality Criteria

1.Wear Resistance

2.Precision.

3.Corrosion Resistance

4.Impact Strength

5.Toughness

6.Modulus of elasticity,Rigidity

7.Transverse Rupture Strength. Etc.

FAQ

Q1:Do you produce special punch mould or punch die components?

A: Yes,we specialize in customized mold fabricate and translate the most complex punch dies idea into reality, punch mold components manufactured by us are designed and customized for various demanding applications and variety materials!

Q2:Do you accept low volume for sample order? And what’s your MOQ for customization?

A: Yes, we do. For sample order, MOQ one piece is accepted. Please attach CAD drawings/3D drawings to your inquiry and the sample lead time is 10~15 days. It can be negotiated for other special requirement.

Q3:If we want to cooperate with you, is it possible to get confidentiality?

A: Sure, all your information including company info, drawings, PO details will be kept confidential, we can signed NDA if you want (non disclosure agreement).

Q4: What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q5: what can you buy from us?

A: Carbide insert,carbide end mill,carbide drill,carbide boring,cutting tools&customized carbide precision molds.