Introduction:

We can produce and process hot runner cemented nozzle core sleeve, hot runner carbide nozzle inner rod blank product.

Hot Runner Systems is a heating assembly system used in injection molds to inject molten plastic particles into the cavity of mold. The hot runner mold is a new structure. When heated, the sprue and the runner of the conventional mold or the three-plate mold are not required to be taken out at each forming.

The advantages of high temperature resistance, corrosion resistance and wear resistance of tungsten steel is the good choice of the hot runner nozzle core and nozzle core sleeve. The hot runners are divided into two types, the open type (used for micro semi-hot runners) and the needle valve type (used for adiabatic runners). The structure of open type is simple and suitable for micro semi-hot runners. The adiabatic runners have higher limitations on materials. And it directly contacts the surface of the product. Thus, it is prone to cause drawing and leakage, and the surface quality is poor.

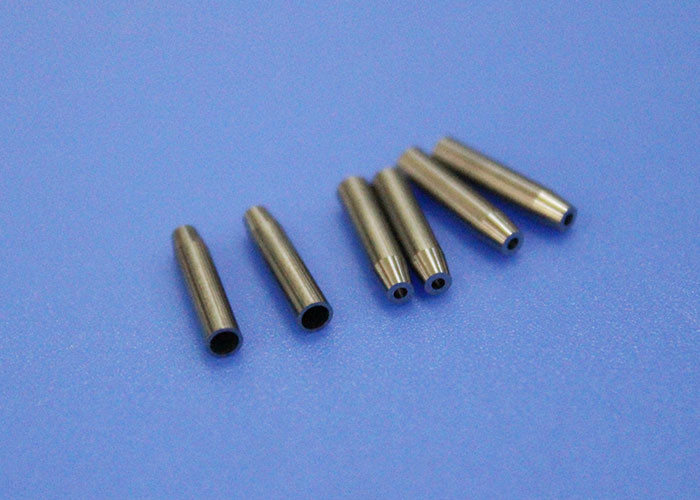

We can provide the high-end hot runner system overall solution. We provide tungsten steel hot runner nozzle core sleeve blank product, which is composed of tungsten steel core sleeve and tungsten steel nozzle inner rod. We can provide hot runner system fine size processing.

Technical parameters:

The tungsten steel hot runner nozzle core sleeve blank is mainly composed of tungsten steel core sleeve and tungsten steel nozzle inner rod.

Advantages:

The tungsten carbide nozzles used for high-precision equipment require good physical stability. Cemented carbide is a good choice for its high-temperature resistance, corrosion-resistant, which can be used for long-time operation. From the selection of raw materials to the deep processing of tungsten steel, each procedure will directly affect the performance of cemented carbide nozzles. As a cemented carbide production and processing manufacturer, we have been committed to providing high-performance cemented carbide products for the mechanical industry. From blank production to deep processing, relying on the advanced cemented carbide production technology and the complete cemented carbide industrial chain in Zhuzhou, we provide customers with high-quality tungsten carbide nozzle and other tungsten steel processing precision products. With the professional production equipment and rich experience as guarantee, we select high-quality materials to meet customers' demand.