Introduction:

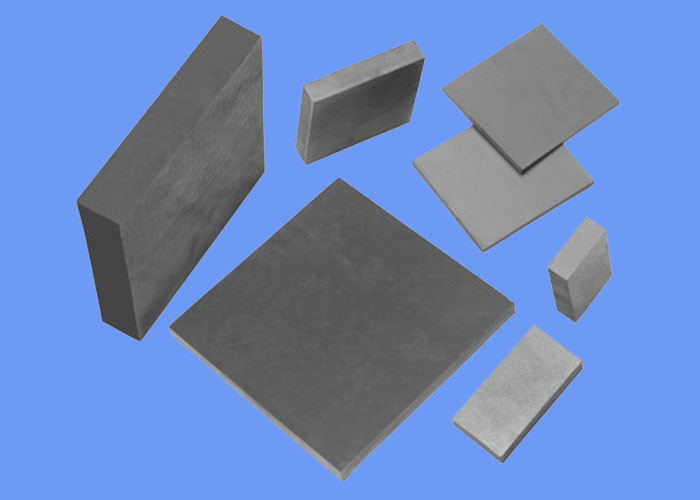

3D glass hot-bending tungsten steel mold sheet, also known as 3D glass hot-bending tungsten steel mold soaking plate, is a soaking plate high-temperature pressing material used in glass hot bending machine. We can produce 3D mobile phone glass screen and glass lens hot bending pressing soaking plate tungsten steel mold material.

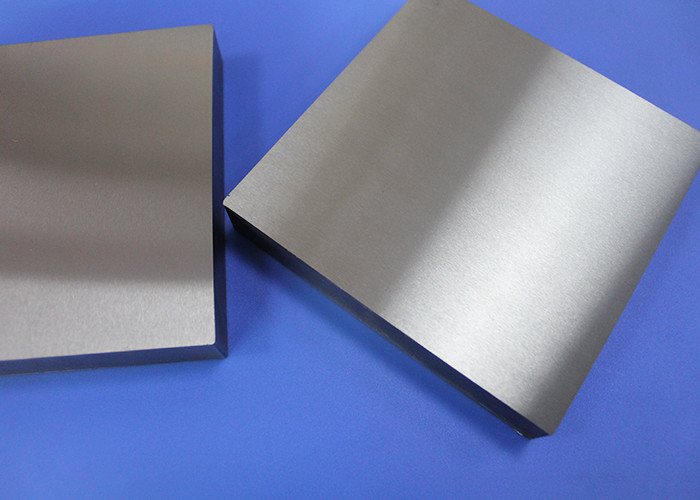

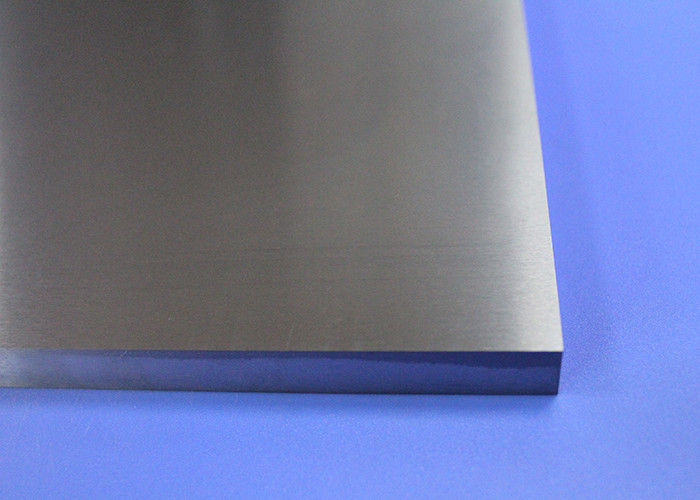

The most important production process of mobile phone 3D glass screen and glass lens is hot bending forming. In the process of high temperature hot pressing in hot bending machine, it is necessary to use high temperature and heat conductive powder metallurgy soaking plate for high-temperature and hot-pressing operation. The heating temperature will reach 950 ° C ~ 1150 ° C or even higher. In such high temperature working environments, it has special requirements for 3D hot bending glass tungsten steel mold. Moreover, the glass material has a strong corrosive effect under high temperature conditions. It is necessary to ensure the compactness and high hardness of the soaking plate, also need to ensure high temperature resistance, heat conduction and extremely high corrosion resistance without deformation. This is undoubtedly a new material application requirement and challenge for powder metallurgy new materials. Powder metallurgy is a process technology for preparing metal materials, composite materials, and various types of products by forming and sintering metal powders. After special treatment by special process, this new powder metallurgy material for high temperature hot pressing operation of 3D glass hot bending machine has strong anti-oxidation ability, good high temperature thermal stability and micro deformation under the high temperature hot pressing working environment of 950 °C-1100 °C.

The detailed dimension of 3D hot bending glass tungsten steel mold soaking plate is customized according to the requirements of customer. The high temperature use requirements of mobile 3D glass production demands that the powder metallurgy materials are of high temperature resistance and corrosion resistance in long-term hot-pressing production conditions.

Generally, the conventional operation needs 3 upper and 3 lower heat plates. That is one set of equipment needs to be equipped with 6 hot-rolled glass tungsten steel molds which are specially processed. Durable life, high temperature resistance, heat conduction and corrosion resistance are the quality requirement for hot bending molds, which involves the mass production of high-end powder metallurgy new materials. As a cemented carbide manufacturer in Zhuzhou, we rely on 60-year cemented carbide military technology and perfect industrial chain in Zhuzhou. And we cooperate with Central South University and other high-level powder metallurgy institutes to provide high quality and suitable powder metallurgy materials for the society. Especially, we can provide powder metallurgy high-temperature tungsten steel mold materials for mobile 3D glass hot bending production.

Technical paramters:

3D glass has the characteristics of light and thin, transparent and clean, anti-fingerprint, anti-glare, hard, scratch-resistant, weather-resistant, etc. It can be molded to make 3D multi-shape appearance with special design of novelty and texture, and can increase the arc shape and edge touch function to provide an excellent touch feel and a better grip experience. The invention of new communication technologies such as 4G, 5G, and wireless charging lamps has promoted the application of 3D glass on mobile phones. Mobile phone 3D glass bending demands high-temperature resistance for powder metallurgy materials. 3D glass hot-bending tungsten steel mold sheet is the main component of hot bending work.

The most important production process of mobile phone 3D glass screen and glass lens is hot bending forming. In the process of high temperature hot pressing in hot bending machine, it is necessary to use high temperature and heat conductive powder metallurgy soaking plate for high-temperature and hot-pressing operation. The heating temperature will reach 950 ° C ~ 1150 ° C or even higher. In such high temperature working environments, it has special requirements for 3D hot bending glass tungsten steel mold. Moreover, the glass material has a strong corrosive effect under high temperature conditions. It is necessary to ensure the compactness and high hardness of the soaking plate, also need to ensure high temperature resistance, heat conduction and extremely high corrosion resistance without deformation. This is undoubtedly a new material application requirement and challenge for powder metallurgy new materials. Powder metallurgy is a process technology for preparing metal materials, composite materials, and various types of products by forming and sintering metal powders. After special treatment by special process, this new powder metallurgy material for high temperature hot pressing operation of 3D glass hot bending machine has strong anti-oxidation ability, good high temperature thermal stability and micro deformation under the high temperature hot pressing working environment of 950 °C-1100 °C.

Advantages:

As the primary productive force, science and technology continue to change to meet the demand of product and social consumption, especially in the mobile phone industry. As the leader in the mobile phone industry, Apple plans to replace the next-generation iPhone with a double-sided glass design of 3D cover glass and back glass, which makes 3D glass another new hot spot after the OLED concept. The glass covers used in digital products are now divided into 2D glass, 2.5D glass, and 3D glass. 2D glass is ordinary flat glass without any curved design; 2.5D glass is flat in the middle, but the edge is curved; and 3D screen is curved in the middle and on the edge. The promotion and application of 3D glass by mobile phone manufacturers has become the trend of the future. The hot bending machines of many equipment manufacturers have been put into mass production. To obtain the large-scale production of mobile 3D glass, the hot bending forming process is indispensable. The demand for high-temperature resistance of powder metallurgy materials is a new technological breakthrough for mobile 3D glass.