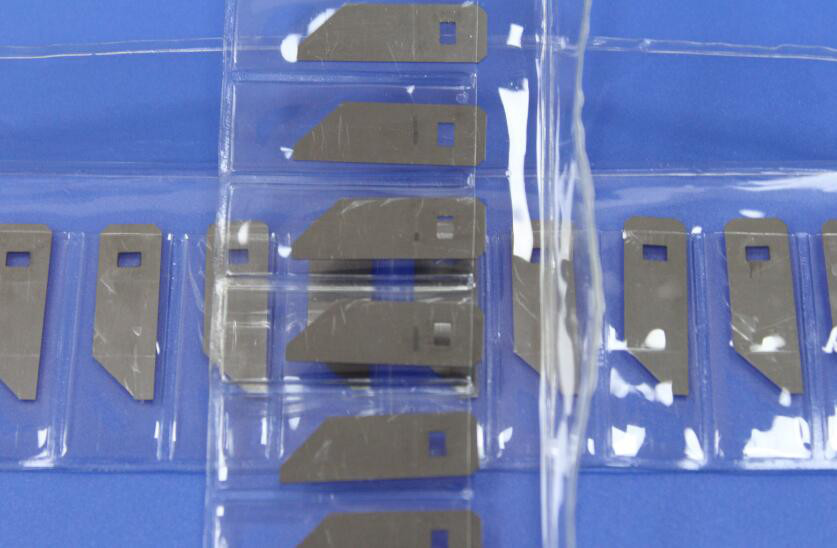

Product Description

Cemented carbide slitting blade, Zhuzhou Sangxin cemented carbide cutting tools manufacturer’s honor product, is mainly used in cutting products ranging from plastic, adhesive tape, corrugated paper, paper packaging boxes, thin film to gold foil,silver foil,copper foil, aluminum foil, magnetic tape.

Cemented carbide is deemed as industrial teeth, whose superior properties make cemented carbide blades become durable sharp cutting tools of high efficiency. Compared with traditional high - speed steel blade, cemented carbide slitting blade obviously shows a more remarkable performance in terms of enduring and efficient mechanical cutting production operation.

Being Zhuzhou cemented carbide blade manufacturer, our company, according to

front-line customers’ application demand, especially the mechanized production requirement for continuous and permanent cutting operation in adhesive tape, plastic film, corrugated paper, packaging paper, has carefully selected 0.6um subfine grain cemented carbide powder, which has gone through high - precision molding and high - temperature low - pressure sintering and therefore our cemented carbide blade has come into being. The inner micro-structure of cemented carbide blade has good compactness, which not only prevents the edge from flaking during accurate grinding and application, but also improves the finish of cutting section and the possibility of one-time cutting forming. Our cemented carbide slitting blade has adopted high-precision grinding machine fine grinding edge. The edge is of high machining accuracy, therefore its surface finish is comparable to mirror. The edge is sharp, so its cutting section is flat, smooth and free from burr and flaw. The blade is solid and hard-wearing, whose edge is sharp. Our blade’s cutting cycle of a single installation machine is everlasting, which is 10 times longer than that of high speed steel slitting blade. Let alone our cemented carbide slitting blade after coating treatment, whose lifespan is tens or even hundreds times longer than that of high speed steel slitting blade. Besides specifications as acid and alkali resistance, corrosion resistance, oxidation resistance, no rust, etc, our blade can adjust variable cutting environments. Our company's standard large-scale production, standardized production process and strict quality control perfectly combined to cast a stable product quality, especially for long-term cutting operations, to help you get rid of worries.

Based on quality, focus on brand. Our cemented carbide slitting blade is wide used by mechanical equipment in slitting paper products, adhesive tape, plastic film, electric wire, rubber, chemical fiber, aluminum foil, multi-layer packaging material, leather cloth, printing cigarette, food, cloth, etc. Our cemented carbide slitting blade is one of the sharp cemented carbide blades, whose precision requirements in slitting operation is particularly meticulous.

Technical parameters

Zhuzhou Sanxing cemented carbide slitting blade, made of cemented carbide (tungsten steel), has gone through multiple producing processes. Our slitting blade is undoubtedly sharp-edged, applied to slitting paper products, adhesive tape, plastic film, electric wire, rubber, chemical fiber, aluminum foil, multi-layer packaging material, leather cloth, printing cigarette, food, cloth, etc. According to different specifications of different slitting machinery and equipment, here’s some common specifications of slitting blades:

1.Ф240×Ф130×1.3

2.Ф268×Ф158×1.4

3.Ф200×Ф122×1.1

4.Φ260×Φ114×1.4

5.φ270×φ168.3×1.4