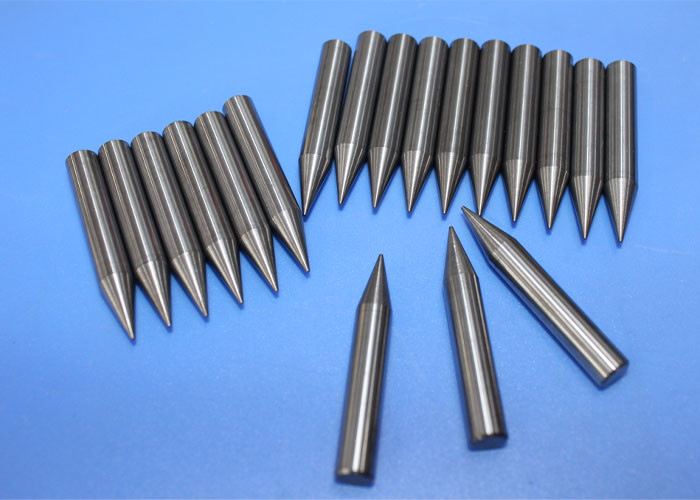

Unnoted Round Corner R0.5 Tungsten Carbide Processing , Tungsten Steel Winding Head

Introduction:

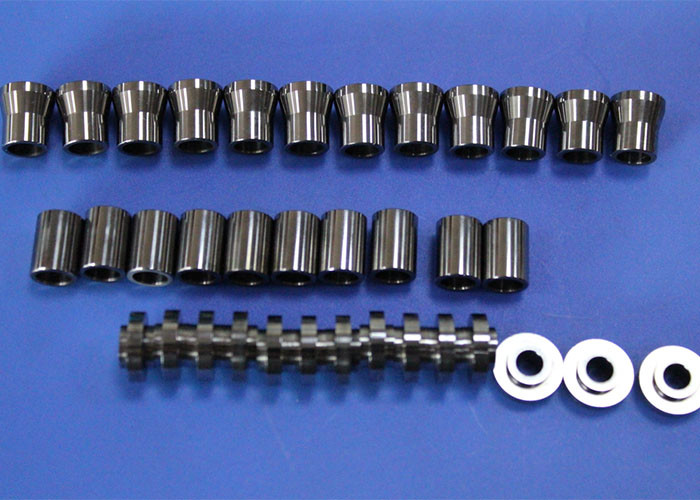

We can produce the non-standard carbide winding sleeve according to the drawings of the automatic winding equipment.

Technical parameters:

The tungsten steel winding head is mainly used for the production and processing of enameled wire winding, requiring long-lasting service life, wear resistance and durability. High wear resistance is the basic requirement for mold products, especially for the long-term operating mechanical equipment such as progressive molds, combined molds and multi-station molds. The cemented carbide mold materials have the excellent performance of long-lasting operation. As a tool material, cemented carbide is a good choice for mold products due to its high hardness, high strength and high wear resistance. According to the actual production operation, we can provide tungsten steel mold parts non-standard customization, according to the customer's specific drawing and confirming the accuracy tolerance.

The tungsten steel winding head is produced and processed according to the drawings. There are 6 special requirements:

- If the dimensional tolerances are not noted, we will produce in accordance with GB/T1804-f. And if the geometric tolerances are not noted, we will produce in accordance with GB/T1184-h.

- The outer surface roughness of the cemented carbide parts is Ra0.025, the roughness of the wire hole is Ra0.1, and the hole radius is R0.15.

- Unnoted round corner: R0.5.

- There are 20 wire holes of φ0.65, and the distance between them is 1.05mm,

- Hard alloy material hardness: HRA90

- Tungsten steel material bending strength: 2300N/mm²

Among them, the 20 through-holes have higher processing precision requirements. They must be consistent, and the operation is fixed according to the four internal thread positioning holes on both sides Every procedure of cemented carbide precision machining needs to be strict and careful, to avoid scrapping of carbide products.

Advantage:

As a wear-resistant industrial metal, cemented carbide is effective manufacturing tool. As a cemented carbide manufacturer, relying on the cemented carbide production technology and complete industrial chain in Zhuzhou, with professional production equipment and rich experience, we provide customers with high-quality carbide mold parts, wear-resistant parts, non-standard shaped carbide products. Based on customer's drawing and selecting high-quality materials, we are willing to satisfy customers' demand to the utmost extent.