Wear Resistance Carbide Mold For Mobile / Laptop / Digital Cameral

Carbide Mold Introduction

Brand Name | OEM |

| Die Tipe | Precision tungsten carbide punch |

| Draw Format | Auto CAD/DWG/PDF ect |

| Tolerance | ±0.002mm |

| Hardness | Upon request |

| Mould size | Customized size |

| Production Application | Mobile/ laptop/ digital cameral/ HD digital TV/ automobile/ electron ect |

| Certificate | ISO 9001:2008 & ISO 14001:2004 |

| Surface Tratement | Polishing/ mirror polishing/ plating/ heat treatment or according to your parts |

| Precision Machining | CNC/ surface granding machine/ punching machine/ sandik wire cutting/ EDM/ WIDA optical curve grinder ect |

| Measuring Instruments | Profile projector/ electronic height gauge/ 2D measuring instrument/ vernier caliper/ microscope/ micrometer ect |

| Steel Material | KD20/ DC53/ GD650/ SKD11/ SLD/ YG15/ CR12MOV/ SKH-9/ Tungsten ect |

| Mould Life | Depends on the steel material and your request |

| Main Service | Made-to-order |

Carbide Mold Details:

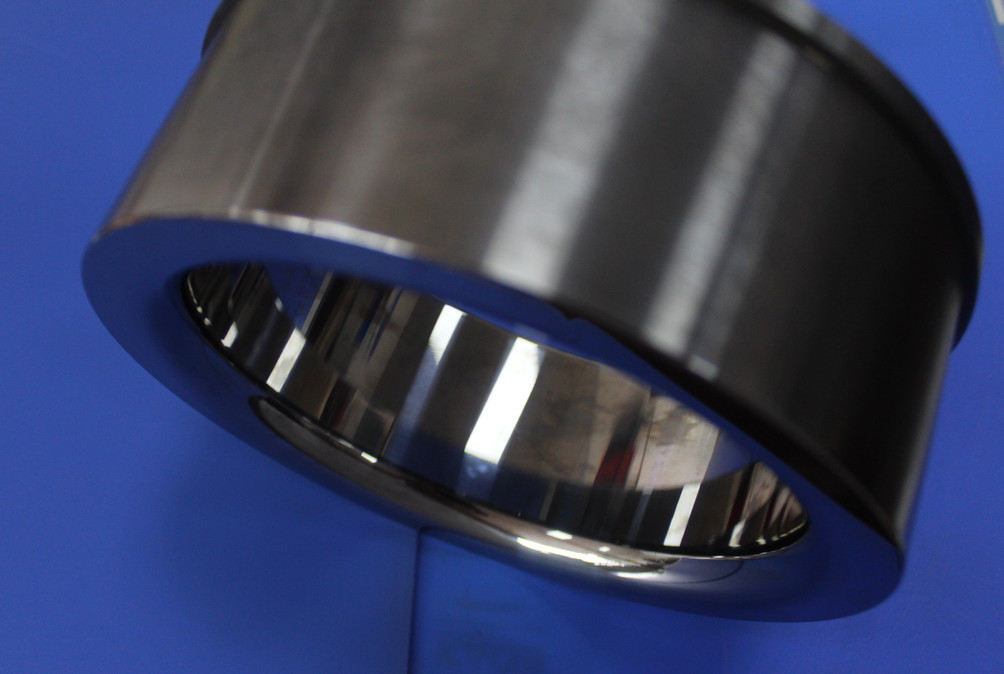

Carbide LCD module indenter, as carbide mold-making product, is hard alloy wear-resistant part. Our company provide LCD module lamination series wear parts according to the drawing requirements for LCD industry equipment. It is made up of the upper indenter and the lower indenter.

The product is the lower indenter of the hard alloy LCD module wear parts. It is formed by pressing and sintering semi-finished blank carbide material. The internal thread is directly formed and processed in the semi-finish production process, and the surface is machined by precision machine tool. After fine grinding treatment and precise size control processing, it becomes the upper indenter. The flatness should be 0.008, and the perpendicularity should be 0.02. The hardness is between HRA92.5-93, meeting the basic super wear resistance requirement. Adopting special cemented carbide production process, it is sintered at 1300 °C high-temperature by professional vacuum low-pressure sintering method. Thus, the metallographic structure is compact, no sand holes and no bubbles. And the internal thread is semi-finished during the blank forming, so it is more convenient to process and sinter the subsequent precision of thread size. This is advanced technical manifestation for the sintering of cemented carbide blanks, and it is also precise control of the dimensional accuracy.

Technical parameters:

The hard alloy LCD module indenter is tungsten steel wear part produced by hard alloy mold. It is used with the wear-resistant parts of the LCD industry. As the industrial tooth, cemented carbide is the first-choice material for wear-resistant parts with its high hardness, high strength and high density. We can provide custom-made upper and lower indenter according to the requirements of customers' drawings.

As wear-resistant part, it is used with LCD industry equipment such as automatic COG equipment, FOG equipment, POL equipment, etc. The lower indenter is pressed, sintered and formed by the carbide semi-machined blank. The internal thread is directly formed and processed in the semi-finished production process, and then the surface is refined by the precision machine tool. And the dimension is precisely controlled to be finished carbide wear-resistant part upper indenter. The flatness and the verticality are both according to the equipment standard.

Advantage:

As a cemented carbide manufacturer in Zhuzhou, we rely on the cemented carbide production technology and combine with years of production experience and advanced processing equipment to provide alloy molds, carbide wear parts, and hard alloy parts. According to the customer's specific requirements and drawings, we provide the best service to meet the needs of our customers.