Wear Resistance Hardened Steel Punch / Customized Tungsten Carbide Parts

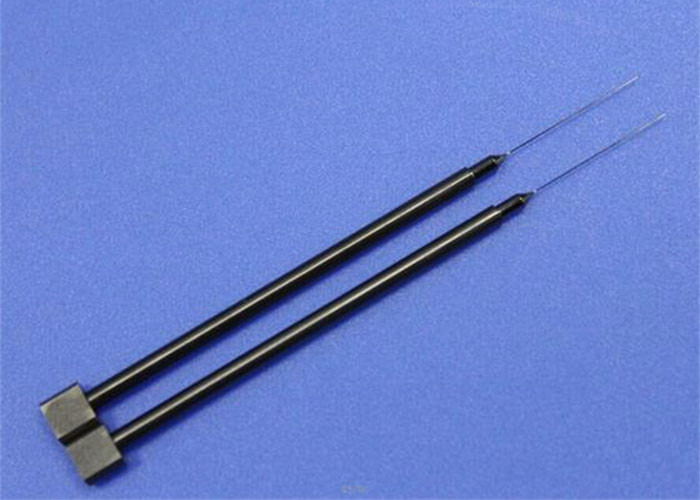

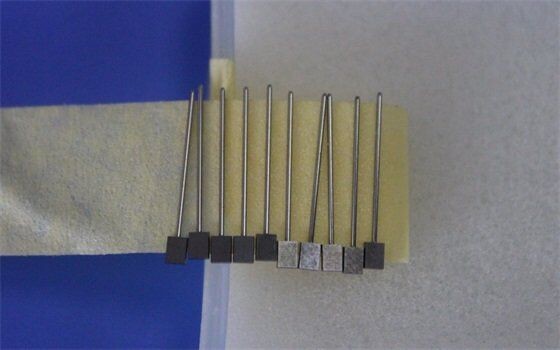

We can provide tungsten steel punch stator core punching needle, punch needle, stator core stamping die and the relevant punch needle.

The hard alloy punching needle is used as the core component of the stamping die because of its excellent material properties. The punching needle is mounted on the stamping die for continuous punching operation, so that the processing material is separated or plastically deformed to get the finished product or semi-finished product. In the cold stamping process, the material is processed into parts. Stamping is a pressure processing method that puts pressure on material by means of the die mounted at room temperature to cause separation or plastic deformation to obtain desired part. It is relatively common in industrial production. Stamping dies are indispensable process equipment for stamping production and are technology-intensive products. The quality, production efficiency and production cost of stamping parts are directly related to the precision and design of die parts.

According to the customer's stator core stamping die drawing requirements, we can produce stator core stamping die forming punch, stator core stamping die stator punch, anti-vibration rotor core stamping die shockproof rotor forming needle , stator core stamping die stator forming needle.

| Name: | Hardened Steel Punch | Size: | Costum |

|---|

| High: | Costum | Advantage: | Wear Resistance |

|---|

| Model: | Tungsten Steel Stator Punch | Tungsten Steel Pin: | Double-hole Insert Head |

|---|

Hardened Steel Punch Advantage:

Material is the main way of improving industrial mass production efficiency. The precision alloy die used with tungsten carbide punching needle and tungsten steel punch has high precision requirements and product consistency. Every tungsten steel punch must strictly meet the dimensional accuracy tolerance, thus can extend the service life of the die. The precision requirements for the cemented carbide parts are μ-level precision. This requires strong technology and rich experience in cemented carbide deep processing systems with advanced production equipment to meet μ-level precision tolerance requirements. As for the processing precision, the production precision alloy parts tolerance can be ± 0.002, concentricity and parallelism can be 0.002. The precision tolerance of the die parts can solve the overall accuracy.