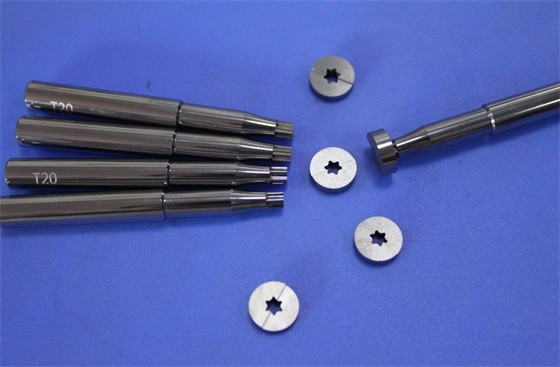

Wear Resistance Tungsten Carbide Pins For Engraving Metal Customized

Tungsten Carbide Pins Introduction:

Hard alloy has high hardness, wear resistance, strength and toughness, good heat resistance, corrosion resistance and a series of

excellent properties, especially its high hardness and wear resistance, even in 500℃ temperature is basically unchanged, still has

a very high hardness in 1000℃

Tungsten Carbide Pins Feature

- Wear resistance

- Toughness

- Fatigue fracture performance

- High temperature resistance

- Corrosion resistance

For the requirements of precision mold machinery manufacturing enterprises in Suzhou area, our company produces custom-made precision tungsten steel rear mold inserts pins. The specifications of the drawings are as follows:

The size specification of tungsten steel rear mold insert pins is PCA-6/2.5/1.03/0.013*48.823L and the tip size is φ0.013. It belongs to ultra-precision fine inserts pin and need to be equipped with precision injection molds for fixed molding operations. The precision requirements are very high. The whole set of molds requires the consistency, each specification is to ensure the precision production of the injection molds.

Technical parameters:

The custom-made tungsten steel rear mold insert head diameter is φ0.013. by high-quality tungsten steel material and then deep-precision processing, the injection mold tungsten steel rear insert pin is tested and qualified by precision testing equipment.

Tungsten Carbide Pins Advantage:

National high-tech enterprise certification, the accuracy of the shape tolerance is ±0.002.