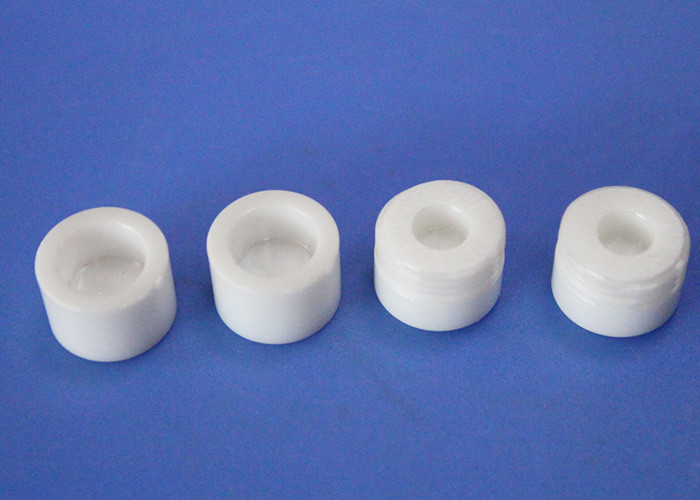

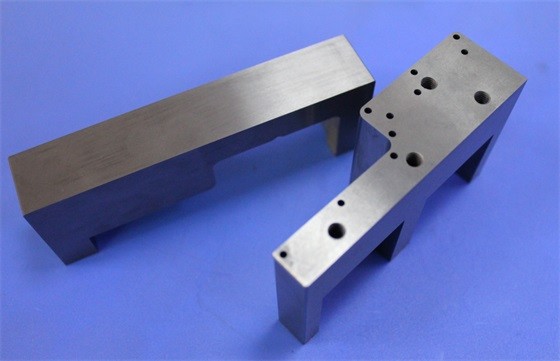

Wear Ressistance Zirconium Oxide Zirconia Special Parts Alumina Ceramic PistonZirconia and Alumina materials are getting more and more popular and well received.

It has been found that Alumina Ceramic Piston, also can be made by zirconia, which is a promising HPLC packing support.

Zirconia cloth is an ideal separator material for the alkaline batteries.

The products of zirconium oxide are gradually adopted in domestic appliances.

According to different aluminum oxide content, or zirconium oxide content for hard ceramic products, the material density is different:

eg.:

| Content percentage | Density |

| 95%-96% | 3.7-3.8g/cm³ |

| 99% | 3.8-3.9g/cm³ |

Key Points:

| Material Grade | AO-1,AO-2,AO-3 |

| Raw Material | 100% virgin aluminum oxide, zirconium oxide |

| Processing | Sintering, Grinding, Polishinig, etc. |

| Replacement | Can be replaced |

| Requirement | Good impact resistance and wear resistance |

Basic properties:

1. High hardness and high wear resistance

2. High elastic modulus

3. High compressive strength

4. Good chemical stability (acid and alkali corrosion, high temperature oxidation)

5. Low impact toughness

6. Low expansion coefficient. The thermal conductivity and electrical conductivity is similar to iron and its alloys.

7. Mostly white color

Applications:

Solar Panel new energy industry

Petrochemical industry

Medical industry