Zhuzhou Carbide 18/25mm Wear Resistant Coal Mining Tungsten Carbide Buttons

Nano cemented carbide which means the WC grain size is less than 0.2μ m cemented carbide, nano cemented carbide has higher hardness and strength than normal cemented carbide, at the same time ,effectively solves the problem of ultra-high speed cutting of hard to machine materials such as superalloy, titanium alloy, composite material, hardened steel, etc., greatly improves the machining efficiency, and is the preferred tools material in the aerospace field and high-end equipment manufacturing industry. Extra coarse-grained cemented carbide is a kind of cemented carbide with WC grain size larger than 6 μ M, compared with coarse grained cemented

carbide, it has better toughness, thermal fatigue resistance and higher wear resistance. It is widely used in shield, mining, stamping die, cold heading die, roll and other industries under extreme working conditions, and the product reliability is greatly improved.

Standard Specifications:

| Dimensions(mm) | Density

(g/cm3) | Hardness

(HRA) | TRS(Mpa) |

| Diameter | Height |

| 20 | 25 | 14.50 | 87.50 | 2400 |

| 22 | 35 | 14.50 | 86.00 | 2480 |

| 24.8 | 33 | 14.50 | 86.50 | 2600 |

| 25 | 35 | | | |

| 26.5 | 38 | | | |

The Coal Mining Tungsten Carbide Buttons can be customized according to your drawing to match your drilling tools, too.

It has complex application environment, engaged in underground coal mining with unclear geological components, and high-power equipment such as propulsion force and shear force, which requires the tungsten carbide buttons to have good impact resistance, heat resistance and wear resistance.

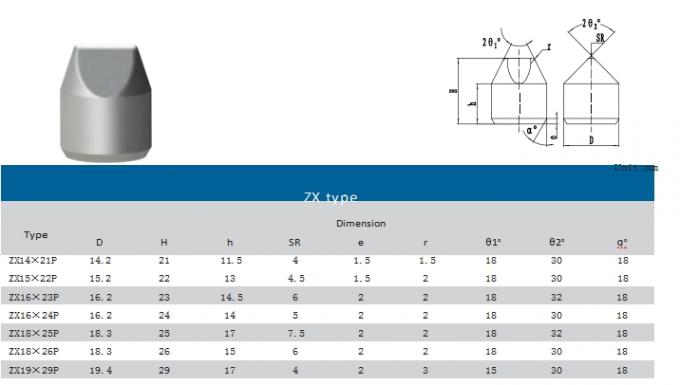

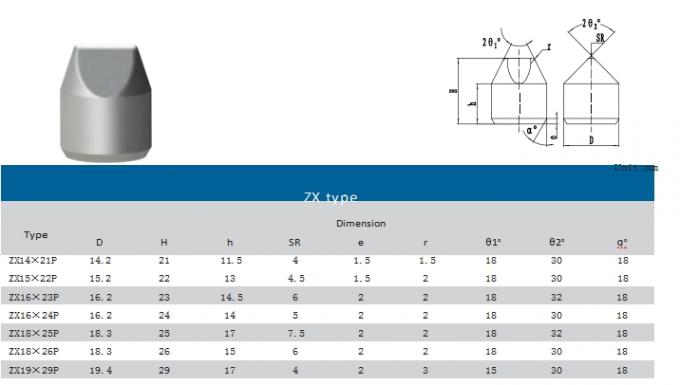

Wedge buttons

Applications:

Polyconical, Parabolic and Mushroom Tungsten carbide buttons, are the general buttons shapes for coal mining series.

Suitable for welding coal mining, coal mining machine in mid-soft rock formation, tunnel excavation in hard rock formation, drilling on extra hard rock formation or tunnel excavation in complicated rock formation.